A water heater is one of many areas a home inspector inspects and often it is one area where we find defects or safety hazards. Although some of the rules have changed over the years; water heater safety is still of upmost concern. Did you know for instance that if the safety features of a water heater are disabled it could explode taking your house with it. So below are some of the major things we look for when inspecting water heaters.

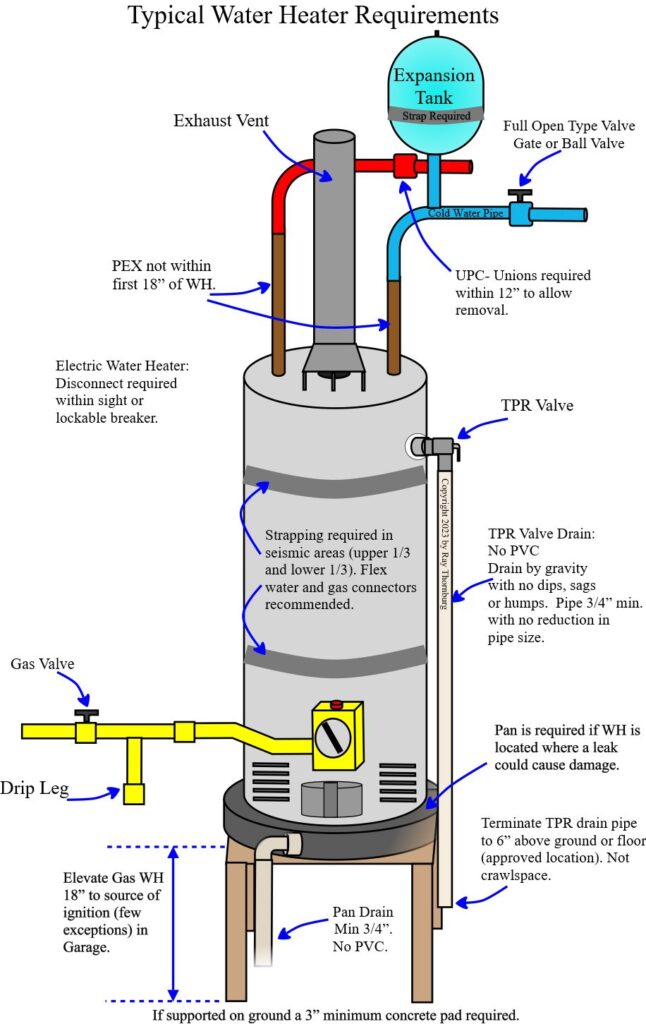

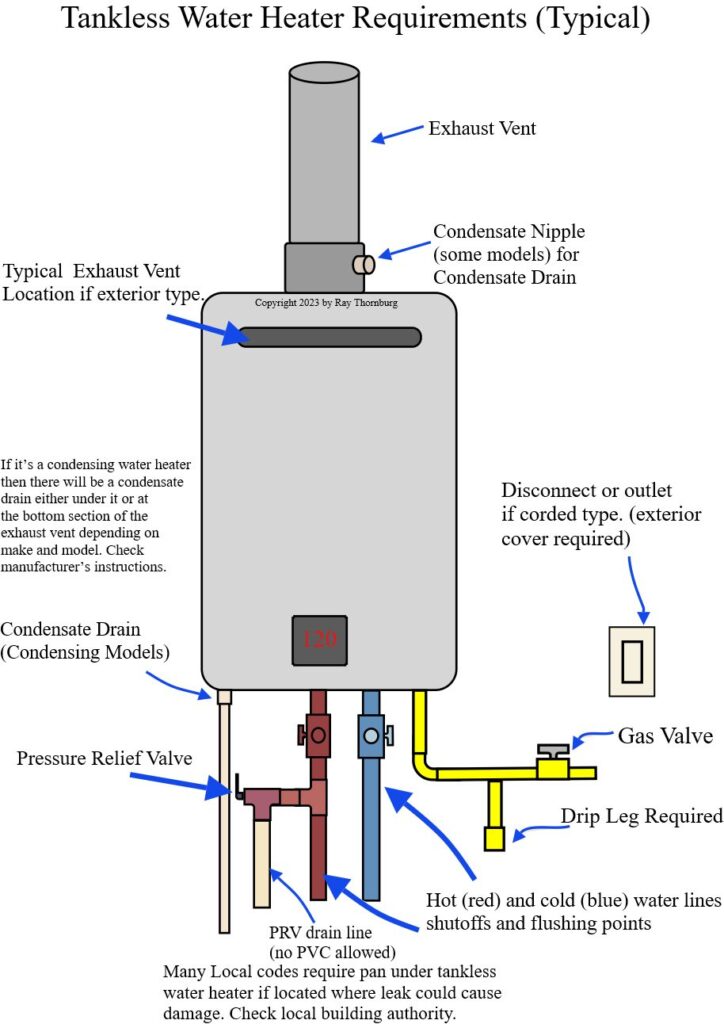

Basically water heaters can be divided into two categories, tank type and tankless. Both types come in electric and gas models. There are some differences between the requirements and allowances for electric water heaters as compared to gas water heaters, namely in the areas of gas safety, location, and combustion and exhaust air. So lets begin our discussion of what a home inspector inspects on water heaters. Check out the photo below.

Rust at fittings is very common on tank type water heaters. If the right dielectric fittings are used this would not be as much of a problem. This tank (above) is actually leaking and is quite visible. When the water heater tank itself starts leaking often it is not so obvious. Often it is a slow process which is hidden behind a layer of insulation. Frequently the only visible signs are a few narrow streaking rusts stains on the outside of the tank.

General Requirements

- They must be sized to meet demand.

- Replacement water heaters require a permit.

- Full open type valve required on the cold water side at or near the water heater.

- Unions are required within 12″ to allow for removal. UPC

- PEX not allowd withing the first 18″ of water heater. UPC

- Seismic bracing required (in seismic areas) upper and lower 1/3 of tank.

- Barrier required in garage (bollards) to protect from vehicle impact.

- Minimum 3″ concrete pad if sitting on ground.

- Remain accessible for service, inspection and removal.

- Must be able to fit through attic door.

- A 30″ x 30″ level working platform required for working space.

- Light and receptacle near the water heater in the attic.

- Light switch required at passageway entrance.

- An electrical disconnect is required to be in sight of the WH or use a a lockable breaker when it’s not within sight.

- Fuel fired WH prohibited in storage closets, bedrooms or bathrooms. Exception- Direct Vent, or in a dedicated enclosure with a solid self closing door, weather stripped and all combustion air from exterior.

- Not to be installed where flammables are stored. (UPC and Manufacturer’s requirement)

- Elevate fuel fired WH at least 18″ above ignition source in garage. Exception is FIVR (flammable Vapor Ignition Resistant). Note* The CPSC (Consumer Products Safety Commission) has mandated that all tank type water heaters be the FIVR type since 2002. However most local codes will require 18″ anyway. It’s standard practice in most areas and is a common sense safety procedure even if it’s not in the garage. Check local code before beginning your install.

- Gas valve and drip leg required at water heater. Commentary- In some areas of the country there is more moisture in the gas supply than other areas. Also changes in temperature and pressure can cause moisture to condense in piping. So a drip leg or sediment trap is required to drain any moisture or remove dirt particles that could block the orifice of gas appliances.

- All water heaters require pressure relief devices and temperature limiting devices. Device may be combination TPRV.

- A Vacuum Relief Valve is required where the water heater is located above the fixture outlets (like in an attic). UPC 2021 608.7 See the vacuum relief valve section below for more information on this.

TPRV Drain Piping

- Drain minimum 3/4″ and equal to or greater than valve outlet. PEX should be one size larger if insert fittings are used.

- Must drain by gravity. Can’t run uphill at any point.

- Cannot be shared with another drain line. Must run independently to exit point.

- No exit to crawl space.

- Exit point must be readily observable.

- End of pipe must exit outside and point down within 6″ of ground or exit to an indirect drain within 6″ (air gap).

- IRC allows exit to pan. UPC does not.

- Commentary- In certain situations exit within 6 ” to a slopped concrete garage floor may be acceptable (not preferred).

- Cannot use PVC as steam will melt PVC.

- If using PEX outside then it must be protected from sunlight. Sunlight will decay PEX sooner than you think.

Pans

- Pan required where leakage could cause damage. Pan minimum depth is 1.5 inches.

- Minimum 3/4″ diameter drain.

- No PVC on pan drain (IRC only). Reference 2021 IRC 2801.6.1

- Pan drain exit to outside 6″ above grade or to indirect drain.

- Pan is not required under tankless water heater (2021 IRC 2801.6). However many local codes will require it anyway. This makes sense and is a good idea if the tankless WH is located in an attic for instance. Check local code department.

Expansion Tanks

Heated water expands a great deal (the greater the heat the greater the expansion) so there must be some way to accommodate this extra volume. While the public utility plumbing is large enough to accommodate this extra volume; this method (of leaving the expansion tank off) is no longer allowed. This is because public utilities are recognizing the need to protect water supplies so new water meters are being installed with back flow prevention devices. So since the adaptation of the 2003 code (P2903.4) a expansion device must be installed. Also any replacement of a water heater installed in an older home since then must have an expansion device. This requirement can be met with an expansion tank or device. So an expansion valve may also be allowed. Check with local code official.

- An expansion valve can be used but some lose of water can occur with an expansion valve. The drain line must exit to an approved location (outside usually). The manufacturer of expansion valves that I’ve looked up state that they are code approved. Expansion valves are not as responsive as an expansion tank so an expansion tank is a much better choice for that reason. However they are less maintenance. Check with your local code official to see if these are allowed in your area.

- An expansion tank is most commonly seen as there is no loss of water on an expansion tank. Tanks have a rubber bladder on one side (like a balloon) that is filled with air to absorb any extra volume from thermal expansion. There can be issues with expansion tanks though. Some of the most common issues are:

Common Problems with Expansion Tanks

- Most common issue is rust at fittings causing leakage. Rust can be caused by dissimilar metals in contact with each other.

- Second most common issue is installing the tank “as is”. Tanks come pre-charged but the amount of air pre-charge is different for each manufacturer. The pre-charge must be adjusted by adding or removing air before installation to match the water pressure of the home. If the pre-charge is less than the normal system pressure (up to 60 psi) then the tank may be too full of water (it’ll sound full when tapped) which can diminish/negate effectiveness. If the tank has too much air then then it’ll (sound empty) and the tank won’t properly absorb the extra pressure.

- An over/improperly pressurized expansion tank can make the TPR valve leak. (common symptom)

- Lack of support strapping can put pressure on piping and fitting is a common defect.

- Ruptured bladder can happen. If the bladder is ruptured then water will come out the air valve when it is depressed. It will also sound full when tapped with a screwdriver.

- An absent or broken expansion tank can put pressure on the piping, tanks, faucets, toilet fixtures causing leaks at intermittent times in those locations.

- A failed or absent expansion tank can have a symptom of a sudden rush of water when the faucet is turned on. The pressure will stabilize and remain stable until the system is non active for a while.

A home serviced by a well would not need an expansion tank on the water heater because there is already a tank type bladder in the well pump tank. Water heaters replaced after the adaptation of the 2003 code or homes built after that should have an expansion tank or expansion valve. If the municipality replaces its water meters for any reason you may need to add an expansion tank even if your house and water heater is old. This is because check valves are sometimes installed when the meters are installed.

Venting and Combustion Air

The most common venting method is the B vent. Click HERE to find out more about B Vents. Other venting methods are direct vent and high efficiency (condensing) vents which can be made out of PVC. Direct vents are often used outside or on the inside against an outside wall of the home. These vents often have a dual pipe which draws in combustion air too. A discussion of combustion air can be found HERE at my old website. Manufacturers will have specific requirements and directions about how their product is to be vented.

Condensate Drains

Condensate drains are found on condensing water heaters. On a condensing water heater the flue gases are not hot enough to carry the moisture out through the vent pipe (unless the pipe is very short) so a condensate drain is needed. Manufacturers instructions should be followed with these drains and they can vary according to configuration. Generally a condensing gas fired water heater located inside should have a trap and sometimes a vent to the drain. This can be a factory made trap or field made. The picture below shows the drain (red arrows) at the bottom left on one model and on the other model it’s a plastic tube with a loop which forms the trap.

Vacuum Relief Valves

It’s important not to confuse this product with other products required for water heaters. The proper term is vacuum relief valve and is required by the UPC for water heaters located above the fixture outlets like in an attic. It is also required for bottom fed tank type water heaters and bottom fed tanks connected to water heaters (IRC P2803.7). The concern this valve answers is the possibility of negative pressure in the tank if the water pressure was turned off and someone opened a valve siphoning water out. Negative pressure in the tank (especially one which is heated) could cause the tank to collapse and that would be a mess. Although some plumbers think this scenario is unlikely they are still required by the UPC. They’re required to be installed in an upright position above the water heater between the water shut off valve and the tank. See the illustration below that helps shed some light on this issue.

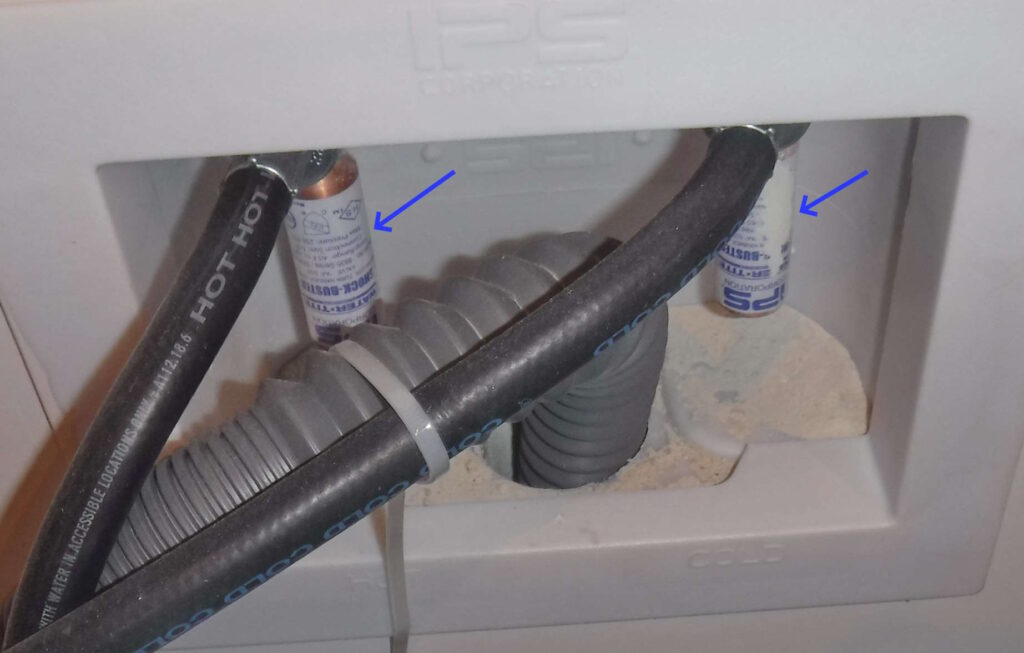

Water Hammer Arrestors

A Water hammer arrestor like the ones pictured above at washing machine bibs are required where there is a quick closing valve. Appliances with a solenoid that fit this description include washing machines and dishwashers. So one is required for the dishwasher and the ice maker too.

Common Problems

- Leaks, Corrosion at fittings.

- TPRV drain line configuration issues.

- TPRV drain leaking.

- Missing drip leg on gas line.

- Missing pan under the water heater.

- Missing drain line on pan.

- Leaks at tank or expansion tank.

- Gas water heater not elevated 18″.

- Venting issues (especially B vents).

- Improper materials used.

Corrosion is a big issue with water heaters. This is because when two different type metals touch each other they start to rust. This is especially true between galvanized metal and copper. To prevent that, they should be separated by a nylon (or plastic) bushing. These fittings are available at hardware stores and sometimes come as a kit. Unfortunately once the corrosion starts, it is hard to stop even if you replaced the fitting. So these fitting should be installed in the beginning when the water heater is first installed.