This article will discuss four popular types of water supply piping we find in modern homes and some surprising issues you probably didn’t know about, but should. Copper, Polybutylene, PEX (PEX A and PEX B) and CPVC.

About Copper Piping

Advantages of Copper Piping

Copper piping in general has a very good track record and has a lot of advantages over other piping types.

- It’s impermeable to chemicals like petroleum products, fertilizers etc. It’s antimicrobial, generally safe and doesn’t leach volatile organic compounds, vinyl chloride or endocrine disruptors.

- It’s reliable and long lasting.

Copper is a micro-nutrient and exists naturally in most water supplies.

It’s strong and resistant to UV light and oxidizing disinfectants like chlorine, chloramines, chlorine dioxide without cracking or failure.

It’s sustainable and can be recycled without loss of any beneficial properties.

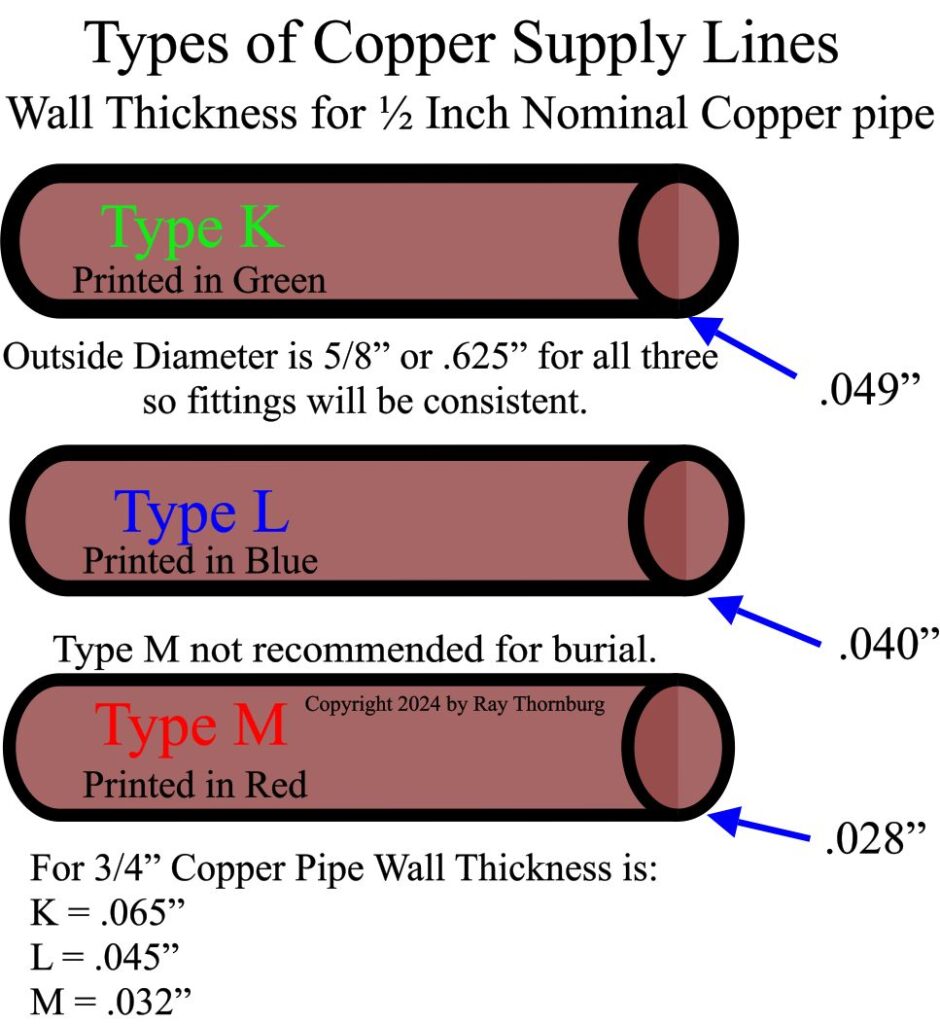

Copper comes in three different grades. If you need more durability and longevity just choose a thicker grade. Type M is the thinnest, Type L is in the middle and type K is the thickest. For durability in water supply piping many plumbers recommend type L.

Disadvantages of Copper Piping

It’s more expensive than plastic pipes.

Corrosion can occur if other metals are not separated from it by a dielectric union.

Type M copper pipe is thinner than the other types of copper pipe and can be subject to leaking over time. In particular homes built in the ’70’s to the mid ’80’s seem to be affected most. It is thought that variations in the manufacturing process or impurities in the metal in those years allowed micro pin holes that would eventually rust through causing leakage. I know that as a teenager growing up in the ’70’s my dad would have me crawl under the house occasionally to patch pinhole leaks with compression fittings. So it was an issue even back then.

Copper pipe exposed to low ph water (acidic) could leach more copper into the drinking water than would be healthy. This is very rare. Evidence of this is blue green staining of fixtures or slightly bluish water where the water isn’t run frequently. Fortunately this is an easy condition to fix.

About Polybutylene Piping

Identification of Polybutylene piping

Polybutylene was manufactured between 1978 and 1994 and was installed in 6 to 10 million homes. You can identify Polybutylene from it’s typical grey color and the stamp on the side which states pb 2110. Although it’s not always grey, however the stamp with 2110 should be on there somewhere.

Failure Characteristics

Polybutylene pipes can burst without warning or leak slowly behind wall coverings causing mold and water damage. It is thought that chlorine in public water cause flakes and micro fissures which leak. Leaks generally occur near joints and the fittings where they are crimped to the connectors. The first generation of connectors were Polybutylene with aluminum crimps. The second generation brass fitting with copper crimp rings were used which is what you’ll find most often. However there is no real evidence that the connectors failed, only the pipe, typically near where they were crimped. The other leakage points were the Polybutylene screw connectors on the fixture supply lines or other places which have a tendency to loosen over time.

At any rate there was a big lawsuit and now the piping is discontinued. It’s important to know that some insurance companies frown on insuring a house with Polybutylene piping so it’s important to note it’s presence on a home inspection report. In this way the homeowner can arrange for repairs or find out the insurance company’s policy before contacting them about insurance.

The Decision to Replace Polybutylene

The decision to replace Polybutylene piping can be somewhat subjective depending on your budget. If your budget allows you can replace it all. If you have well water and brass fittings, the pipe itself may still be holding up well. However a home built thirty years ago may already need new fixtures so cutting it back and adding new stops (shut off valves) and fixture connectors is prudent at the very least. This is what I did. In my case a fixture connector became loose over time and leaked. When I checked my other fixtures they were loose too. Of course I tightened them but for peace of mind I cut them back added new fixtures, connectors and stops. I have well water but be aware that chlorine and other chemicals that are added to water at the municipality can do a lot of damage to all kinds of piping. If I had chlorine in my water and actually saw pinhole leaks or splitting my decision may have been different.

Chlorine Degradation

ASTM F2023 is the testing standard all polyolofin plastic piping (such as PEX, PERT and polypropylene) must meet. Piping meeting this standard is supposed to last 50 years. Polybutylene also falls into that category but it was created before the standard. To make a long story short the molecular structure of these polyolofin plastics will inherently fail over time due to oxidative attacks from chlorinated water. To slow the time frame to failure chemical additive are used. However these additives are sacrificial; meaning over time the protection these additives provide wear out leaving the pipe vulnerable to the chlorine attack and failure. Since the standard uses accelerated tests and extrapolation it doesn’t necessarily represent real world conditions. Since almost all municipalities use some form of chlorine to make the water supply safe to drink it is likely that (unless you have well water) chlorine degradation might be the culprit in premature failure of some piping systems. Only about 15% of homes in the US use well water FYI. It is also noteworthy that most manufacturers have an exclusion in their warranties about “aggressive or chemically corrosive water conditions”.

About the UV Protection

Also consider that PEX is not sunlight resistant and must be protected from sunlight or fluorescent lights. Apparently UV light which is present in sunlight and fluorescent lights can strip away the chlorine inhibiting anti-oxidants. Limiting the products sun exposure before installation may prove to be difficult. Although the manufacturers state that the product has 30- 60 days protection it’s been reported that substantial reduction in resistance to chlorine degradation due to sunlight exposure in as little as one week. So without the chlorine inhibiting anti-oxidants the pipe is more susceptible to chlorine degradation. If there is ever a claim then the manufacturers will look to see if the piping is protected against sunlight. For these reasons you should check the warranty on the type of pipe you have or are thinking of installing in your home.

Legalities

Before I go too far I would like to point out that there have been problems with almost every kind of pipe. Sometimes these issues are resolved over time and sometimes not as in the case of polybutylene which was discontinued. There have also been lawsuits concerning almost every kind of pipe including copper and CPVC, Polybutylene and now PEX. For example for a long time there was a small amount of lead in the solder used for copper pipes. This was eventually remedied. However, lots of pipe manufacturers have also had problems either with the pipe or the fittings and sometimes the companies changes things to make their product more reliable. But there has been some lawsuits concerning PEX piping and among them are Viego, Nibco, Zurn and Uponor and some others.

About PEX Piping

Pex(cross linked polyethylene) started to become popular about the time polyethylene fell by the wayside. It’s the predominate home plumbing material right now. About 60% of new construction homes are plumbed with PEX. Typically PEX is colored red, blue, clear and sometimes grey but that is rare. The color simply helps the plumber distinguish between hot and cold to aid installation. There are more than several different types of PEX but we’re going to focus on two, PEX A and PEX B.

About PEX B

The first PEX we’ll discuss is the one we don’t have as many problems with, PEX B. Pex B uses crimp rings with plastic or brass couplings. PEX B will be red, blue or white and be labeled on the side of the pipe “PEX B”. It’s the predominate type of PEX we find at the local hardware store. PEX B is advertised as being highly resistant to chlorine and is easy to install, with nippers to cut it and a crimp tool for the crimp rings. However PEX B is denser than PEX A and I have read reports that PEX A degrades 5 times faster than PEX B from chlorine degradation. So that’s a major advantage for PEX B. The major disadvantage is that on PEX B the fittings fit inside the pipe so it can reduce the flow. On residential installations in most cases this isn’t going to be a big deal. Although PEX B appears to be more reliable than PEX A there have been lawsuits on this type of pex or its fittings.

About PEX A

PEX A looks almost exactly like PEX B except for the writing on the side of the pipe that says it’s PEX A. You can use crimp rings with PEX A or expandable fittings; which is why many plumbers use it. A special tool is inserted to expand the pipe and the fitting is inserted so that the pipe shrinks back around the fitting creating a water tight seal. In this way there’s no restriction in the water flow. Some other advantages is how quickly it can be assembled and it’s increased flexibility . For a tradesman saving time is saving money. Recently however it’s becoming apparent that there is one brand specific type of PEX A which is presenting problems. Uponor PEX A.

About Uponor PEX A

Formerly known as Wirsbo, Uponor now makes PEX A. A recent lawsuit has spilled the beans on a issue that appears to have been kept hidden from the public in general. That there have been failures in Uponor PEX A; sometimes in as little as seven years or less after installation. Degradation of the pipe, splitting and pinhole leaks are among the complaints. The lawsuit alleges that the process Uponor uses to add color to the outside of the pipe (by heating it) damages it. Other types of PEX A add color before the manufacturing process so the color is consistent all the way through the product. Uponor apparently adds it later by a process the lawsuit alleges damages the product and causes premature failure. Some plumbers theorize that breakpoint chlorination also plays a part in it’s degradation because they can see the damage on the inside of the pipe too. Plumbers also notice that the condition affects the hot water side of the system more.

Uponor apparently has quietly discontinued the coloring process on this type of pipe in 2021. So now the pipe is clear, but it’s uncertain whether the issue of breakpoint chlorination has been solved. It’s not known when the problems started. This kind of pipe may have been around since 1970 in some form or another. In Skimming through customer experiences on the internet I found the issue of failed Uponor Pex A in homes built in as far back as 2005. Uponor piping with this issue will likely have fittings which turn yellow or show signs of plastic corrosion near the fittings. Also if you have red or blue the color is only on the surface. So cutting a section out would reveal this. It will have the brand name Uponor or Wirsbo on the side along with the words PEX A.

The NIBCO PEX Failures

Between the years of 2005 and 2012 a company called NIBCO also had problems with their PEX piping. This pipe is typically clear or translucent and has the brand name NIBCO on it and possibly a date code. Some of these problem pipes can also be burnt orange or reddish. They may also have the words Dura-PEX or CPI (Consolidated Plumbing Industries) written on the side of the pipe. Problems include degraded piping and corrosion on brass fitting and stainless steel crimps. The class action lawsuit was settled and the last day to make a claim will be October 13, 2025 according to their website.

CPVC Piping

CPVC stands for chlorinated polyvinyl chloride and is a type of plastic piping approved for hot and cold water supply lines in homes. It is solvent welded at the fittings just like PVC and is creamy white in color. It is often used in residential construction and re-pipes. CPVC’s biggest drawback is over time it gets brittle and weak. So weak that it could snap off in your hand, if you turn a stuck valve for instance. Some plumbers report failure after only a few years. It’s also a hard plastic so it is subject to freezing damage. Spray foam insulation can damage it. Also it is not resistant to most water insoluble hydrocarbon based chemicals. However CPVC is theoretically at least resists chlorine degradation which can affect Polybutylene, polyethylene and PEX. In fact CPVC is often used in chlorine delivery systems. So it is not known why some CPVC turns brittle over time. We suggest checking warranties. We checked and found warranties varied from 1 year to 30 years depending on the brand. Flowguard Gold for instance had a 30 year warranty and extensive information online about the issue of chlorine degradation. Unfortunately this company has also been named in a lawsuit for piping becoming brittle and failing.

Summary

There are many more types of plumbing piping out there but these are probably the most popular in use today. All types of piping has their advantages and disadvantages. Some have been greatly unhealthy like lead piping. One thing they all have in common is the issue of chlorine degradation. It’s more than just chlorine however. Other chemicals are used, like chloramines, chlorine dioxide, fluoride are also used. These chemicals degrade the pipe but also whatever the pipe is made of also leaches out into the water you might be drinking. For plastic pipe, the leaching of unhealthy volatile organic compounds, toluene, ETBE and others is an issue especially in the first month after installation. Some brands and types appear to leach more than others. After the first month the levels go down but never really go away. Occasionally this leaching causes the water to have an objectionable odor. There’s also the issue that outside contaminates like oil, gas, pesticides, fertilizers and benzene can permeate through the PEX pipe into drinking water. For instance when the pipe is buried.

I was taught that plumbing in a home is supposed to be designed to last a hundred years. While I can’t remember where I learned that; I’m sure that nobody would expect their piping to fail before the mortgage gets paid off. How would you feel if your pipes failed after only 7, 10 or 20 years? What do you think? How long should plumbing supply lines last?

Blue Palmetto Home Inspection Serves Summerville, Goose Creek, Moncks Corner, Holly Hill in SC and Surrounding Areas. Call us today! 843-934-3045

Sources

Zurn Pex Lawsuit | Plumbing Problems, Failure | ClassAction.org

Chlorine Degradation and Chemical Incompatibility in PEX | FlowGuard Gold

PEX Lawsuits | Tubing & Fitting Problems | ClassAction.org

Uponor Class Action Lawsuit: Navigating The Maze Of Plumbing Peril – Lawyer Aspect

Home | NIBCO (pexsystemsettlement.com)

CPVC Pipe Failure (classaction.org)

https://youtu.be/FcHcKvZ3AZE?si=IzgKpSaDLxu8EWdf

Class Action Revisits Settled Case Over Allegedly Defective Shell Oil Polybutylene Piping Systems