The types of wiring systems in homes have evolved over time so this article will not discuss all those types that we sometimes find in old homes. Nor are we going to cover every type of wiring system in use today. That’ll be too big a topic. Instead we’re going to focus on the most common wiring types used in residential homes today, how to recognize them and what to look for. We’re going to talk about where they can be used and some common deficiencies. Let’s get started.

NM Type Electrical Cable

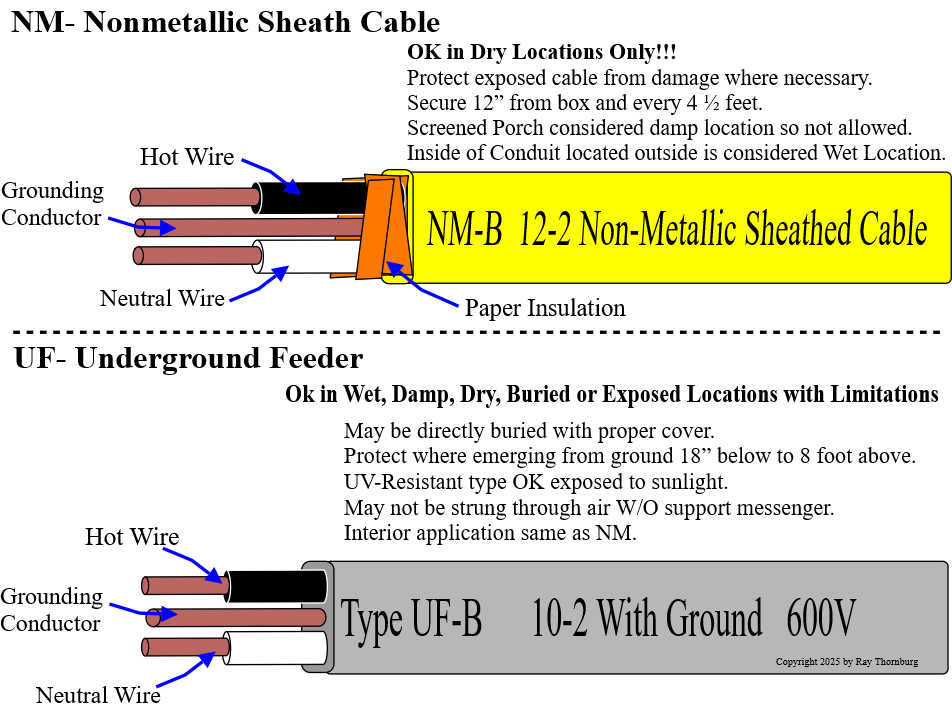

NM stands for non metallic sheathed cable. It is also called Romex after the company that first manufactured it in Rome NY. It first appeared in the 1926 version of the NEC and has evolved over time. At first the outer jacket was braided cotton with a tar like substance and then later the braided cotton was changed to braided rayon some time in the 1950’s. In the 1960’s the outer covering was changed to PVC much like the product we have today. In 1984 NM-B was introduced. While it looked similar to the previous product it had a higher temperature rating. So the B stands for the temperature rating of the thermoplastic which surrounds it. There are several types of NM cable but we’re only going to be talking about NM-B type because the other types are less common now. Type NM electrical cable is in about 90% of the homes in the United States according to the internet grapevine. It’s been around in one form or another since at least 1928 when it first appeared in the NEC.

Color Coding of NM-B Electrical Cable

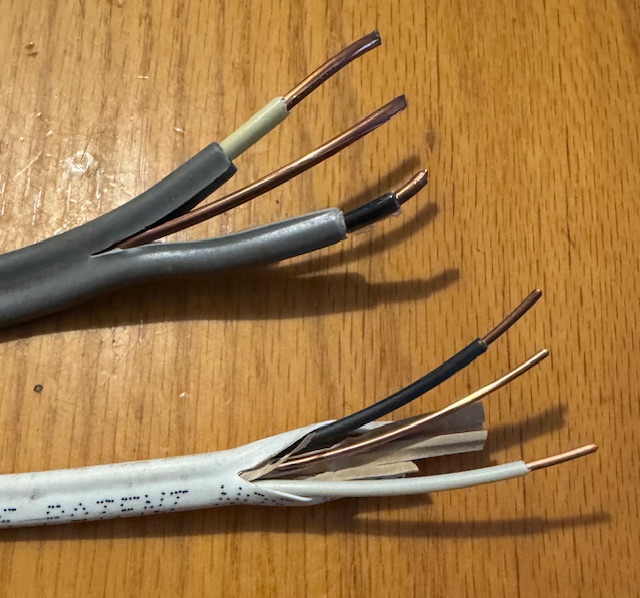

At first all the NM-B cables were white; then in 2001 or thereabouts color coding was introduced. The first number in our descriptions below designate the wire gauge size and the second number the number of conductors not including the grounding conductors. So a 14-2 would actually be three 14 AWG (American Wire Gauge) wires, a hot, a neutral and a bare grounding conductor.

White 14-2 AWG for 15 amp circuits

Yellow 12-2 AWG for 20 amp circuits

Orange 10-2 AWG for 30 amp circuits

Black 8 AWG for 40 amp circuits

Black 6 AWG for 50 amp circuits

Starting in 2024 we’re seeing three more colors on the store shelves

Light Blue 14-3 AWG

Purple 12-3 AWG

Pink 10-3 AWG

Uses for NM-B Electrical Cable

Dry Locations Only for wiring lights, switches, receptacles, outlets and other electrical components.

One and two family dwellings.

Multifamily Dwellings (types III,IV,V) with some exceptions.

For both exposed and concealed work in normally dry locations (with some exceptions). For instance it can be on the outside of a finished interior wall (providing it’s not subject to damage) but not on the outside of an unfinished interior wall.

Protect cable from damage where necessary.

Min. ¼ inch sheathing must enter into the junction boxes.

Secure within 12 inches of box and every 4.5 feet.

Bends minimum 5x cable diameter

Protect when less than 6 foot from attic access.

If less than #8/3 must now use running board to attach conductors to under joists.

Cable shall closely follow the surface of the building finish or of running boards.

- With metal framing listed grommets are required to protect the wiring from the metal edges of the holes in metal framing.

- Cables must be a minimum of 1.5 inches below the steel sheet metal of a metal roof deck.

- NM is not suitable as a flexible cord with a plug on the end.

Wiring device without a separate (junction box) is allowed if the device is listed for it and has a cable clamp. There must be sufficient cable to permit replacement. See the NEC code book for details about this.

- NM would not be allowed on the outside of an exterior wall sheathed with OSB for instance but behind the vinyl siding because that space is considered a wet/damp location.

- NM type electrical cable would not be allowed underneath an exterior deck.

Commentary- Using NM-B in a place which where it is not rated for is one of the most common deficiencies concerning this type of wire home inspectors find. Since NM-B is not sunlight resistant and not rated for damp or wet locations then it can fail prematurely if used in any of those locations. For instance a buried NM cable supplying power to a well pump for instance will eventually fail without notice leaving you without water. (That’s what happened to me!)

With this in mind we must learn about dry, damp and wet locations!

Wet, Damp or Dry Locations

Dry Locations

A location not normally subject to dampness or wetness (except temporarily like a building under construction).

Damp Locations

Locations protected from the weather and not subject to saturation with water or other liquids but is subject to moderate degrees of moisture. Examples of this would be partially protected areas under roofed open porches, canopies, marquees. This could also apply to some basements, some barns and some cold storage facilities.

Wet Locations

Installations under ground, in concrete slabs or masonry in direct contact with the earth, In places subject to saturation with water or other liquids such as a car washing building or in unprotected areas exposed to the weather. Conduit located outside is considered a wet location. Underneath an exterior deck is considered a wet location.

Discussion

There is much discussion about where NM cable can be used. In the field we often find amateur installations where it’s installed in an improper area. Sometimes only a portion of the cable is exposed. Obviously anywhere it’s exposed to sunlight would be improper and anywhere under a porch except maybe in the concealed attic of a porch. NM is not allowed outside even if it is in conduit. Of course much of this is subject to the interpretation of the AHJ (authority having jurisdiction).

UF stands for Underground Feeder. This type of cable is suitable for dry, damp and wet locations and can be directly buried. If it’s rated as sunlight resistant (most are) then it can be strung through the air as long as a messenger wire is used to support it. Its made of a tough solid grey PVC jacket with individual conductors also color coated with PVC. While typically this product is grey in color, some are black. It comes in similar sizes as regular NM-B and is used in a similar way to wire outdoor lamps, pond pumps, well pumps or other purposes.

Uses for UF Type Electrical Cable

Can be directly buried with proper cover (typically 24 inches deep).

Burial depth can be reduced to 12 inches if GFI protected before circuit enters ground. This applies to residential circuits 20 amps or less only. This is located in table 300.5 of the NEC column 4.

Must protect where it emerges from ground to the burial depth and 8 foot above grade.

Single conductors in trench must be grouped.

UV resistant type can be exposed to sunlight.

Can be strung through the air with a proper messenger support wire.

Interior installation rules the same as NM.

For wet dry or corrosive locations.

Can be used for photovoltaic systems.

Bend radius must be 5 times diameter of cable.

Uses Not Permitted For UF Type Electrical Cable

As service entrance cable.

In storage battery rooms.

In hoistways or on elevators or escalators.

Embedded in poured cement, concrete or aggregate.

Where exposed to direct rays of the sun unless identified as sunlight resistant.

Where subject to physical damage.

In commercial garages, theaters, motion picture studios.

See Article 340 of the NEC for more info.

Service Entrance Cables

Service entrance cables bring the electricity from the electric company or the meter box into our homes. The NEC mentions at least two types of service entrance cables. Type SE (Service Entry)cable and type USE (Underground Service Entry)cable. Only the USE cable is allowed to be buried. Both types come as single strands and as a cable assembly (multiple insulated strands in an outer jacket).

Common SE Cable Types

SEU – (Service Entry Unarmored) is not rated for underground use. It’s typically two insulated conductors with a non insulated neutral wrapped around it and an outer gray PVC jacket. Typically used to supply power to the main breaker panel.

SER – (Service Entrance type R) Can be typically three insulated conductors and one non insulated grounding conductor. It is wrapped in a grey PVC outer jacket. It typically can used to feed a sub-panel.

Common USE Cable Types

USE – (Underground Service Entry)- Can come as single strands of insulated wires or as an assembly with an outer PVC gray jacket much like the SEU and SER cable types already mentioned. These cables are rated for underground use.

URD – (Underground Residential Distribution) cable is commonly used in underground utility distribution systems to support secondary power distribution.

Common Conduit Types

Unlike the cable assemblies that we’ve mentioned up till now, conduit is typically wired with individual strands of conductors. These strands are specifically manufactured so they can be pulled through the conduit easily and for the environment in which they are to be used. They are THHN and THWN with the latter one being rated for Wet Locations (note the W in THWN). Some brands have both ratings on them. Typically NM and UF cables are not put in conduit except to protect it from damage. Plus it would be very hard to pull these types of cables through conduit.

LFNC (Liquidtight Flexible Nonmetallic Conduit)

LFNC is often used to protect the conductors for an AC compressor outside or maybe a hot tub. It’s sturdy, flexible rated for outdoor and also direct burial if labeled for it. It is flame resistant. If it’s longer than 6 feet it needs to be secured every three feet and 12 inches from junction points. You must use the approved fittings for the system you have. Most types are gray in color. There are three types.

A type has a smooth inner core.

B type with integral reinforcement.

C type is corrugate inside and outside.

LFMC (Liquidtight Flexible Metal Conduit)

LFMC looks just like LFNC except it has a inner flexible metal core and a bonding wire which encircles with the metal lining. Because of it’s metal core it’s sturdier than the LFNC but it’s a bit more difficult to work with because the metal inner lining has to be cut a certain way for ease of application.

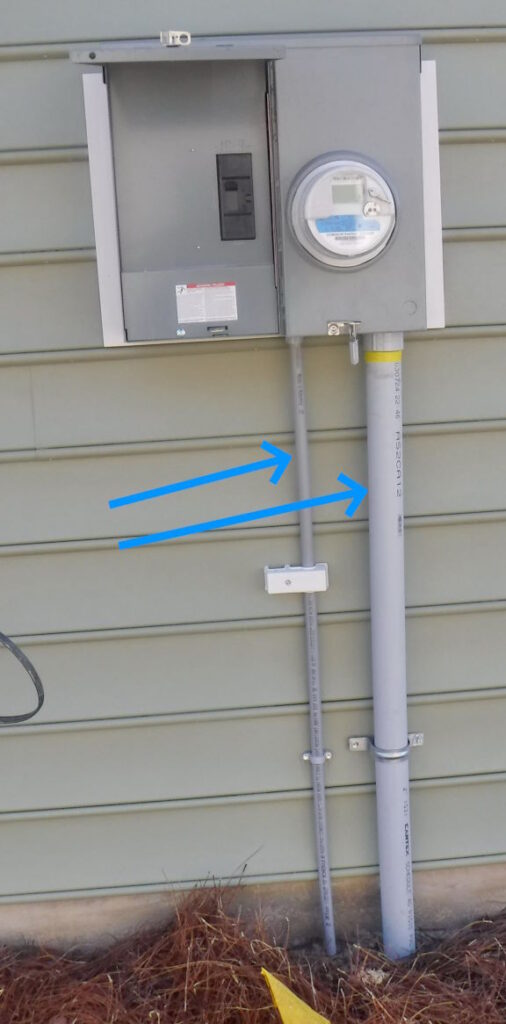

PVC Electrical Conduit

PVC electrical conduit (Rigid Polyvinyl Chloride Conduit) is typically gray in color and should not be confused with the typically white PVC used for plumbing drain lines or for cold water supply lines. The two products are made for different purposes. While both PVC plumbing piping and PVC conduit are available in a variety of colors typically if white PVC pipe is used on electrical components it means an amateur did the electric job and is a defective condition. The systems are not meant to be interchangeable. If it makes it any easier remember that electrical conduit is found in the electrical section of the store and plumbing pipes are found in the plumbing department. Both electrical and plumbing PVC have a schedule 40 and a schedule 80. PVC plumbing piping is used for water flow and sometimes water pressure. PVC electrical conduit is designed to pull wires and contain fire and sparks. The ratings and fitting are different.

There are several different grades. The higher the “schedule” the thicker the pipe wall thickness is.

Schedule 40 PVC electrical conduit.

Schedule 80 PVC electrical conduit. Schedule 80 PVC has a thicker wall and is used where a more robust pipe is needed. In some cases the plans and specifications will determine which type to use.

Schedule 40 PVC plumbing pipe is often used for drain, waste, venting systems of the home. Occasionally it is used for cold water supply.

Schedule 80 PVC plumbing pipe has a thicker wall and can handle higher pressure ratings. Sometimes up to 50% higher.

- Schedule 20 PVC is sometimes used for irrigation and low pressure applications.

PVC electrical conduit has specific properties to resist heat and sunlight degradation. It’s designed to help prevent the spread of fire in case of a short in the electrical wiring.

It can be used inside and outside in wet locations, inside walls, in corrosive environments and underground. There are a wide range of fittings and boxes available for almost any application. Typical applications on a residential home is the protecting the service conductors before and after they enter the meter box. It’s also used to run electrical conductors outside or under porches. They make a variety of waterproof boxes for this purpose.

- If less than 1 inch then the maximum spacing of supports is 3 feet.

- 1 1/4 – 2″ max support interval is 5 foot.

- Fastening methods for support must allow for thermal expansion.

- By itself it’s not allowed to support luminaries or boxes.

- Expansion fittings or slip joints required if subject to movement greater than 1/4 inch.

ENT (Electrical Nonmetallic Tubing)

ENT is a flexible corrugated raceway made of a material which is resistant to moisture and chemical atmospheres and is flame retardant. It can be encased in concrete. It is not rated for wet locations, cannot be used where the sun can degrade it (unless marked as sunlight resistant) and cannot be directly buried (with some exceptions). This product comes in different colors but most people know it as the blue smurf conduit. Different types of conductors can be used in it including THHN, THWN but most often in residential construction it’s used to protect the NM conductors wiring from water heater to wall or under the sink to this disposer. It is also used to protect cable and communication network wires and is often orange in color when used for this purpose. Support requirements is every three feet. Please see article 362 of the NEC for more information about this as there are a lot of exceptions and limitations on this product.

EMT is an unthreaded thin wall metal conduit used to protect wiring. It typically is made of steel with a galvanized or aluminum coating and when used with the proper fittings it also serves as the equipment grounding conductors. The tubing can be bent with a proper tool and there are set screws at the boxes to connect the tubing and provide continuity. Although the tubing serves as the grounding conductor many electricians provide a separate grounding conductor anyway. Type of fittings used is dependent on the environment in which the product is installed. It’s permitted to be used in concealed, accessible, and wet locations with the proper fittings. In residential applications the most likely place to see EMT is in a detached garage, metal building or farm structure.

Armored Cable/ Metal Clad Cable

I’ve saved our discussion of these last two cable types to last because they’re less common in residential construction in most parts of the country now. Some municipalities do require it so here goes. Armored and metal clad cable have a metal or aluminum covering protecting the conductors inside. They’re designed to withstand a certain amount of physical damage and are used in places where regular cables could get chewed on by rodents or damaged in some other way. They’re protected by a spiral-wound outer metal sheathing. There are two main categories: Those with an integrated bonding conductor and those without.

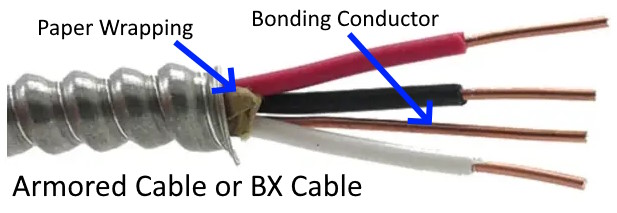

Armored Cable or BX Cable is a manufactured spiral-wound metal casing with conductors wrapped in paper. It has an internal bonding strip of copper or aluminum in intimate contact with the armor for it’s entire length. Special red bushing are required to protect the cables from the metal edges of the casing. It’s approved for dry locations only.

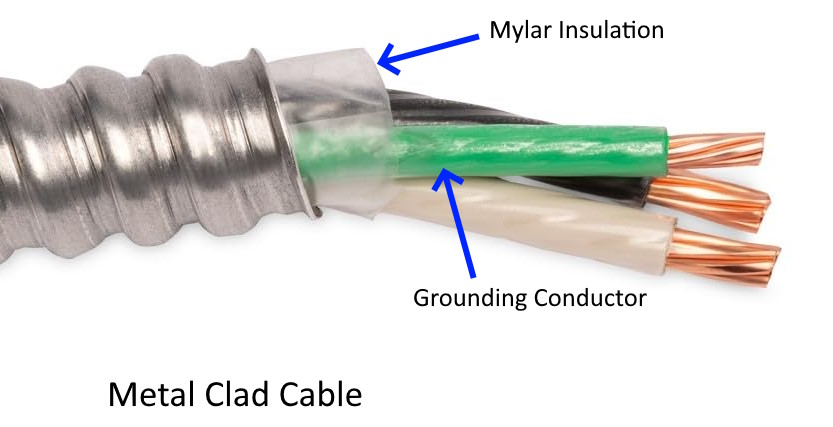

Metal Clad Cable – The regular type looks just like armored cable except it has a mylar sheath surrounding the conductors. It has a separate insulated grounding conductor. On MC cable the metal armor is not a ground. It can be used both inside and outside. Certain types can be buried or used in wet locations if it has an outer jacket that is impervious to moisture and is listed for that use. There are different types of MC cable that this article won’t address. As always see the listing and proper code references for the product you want to use.

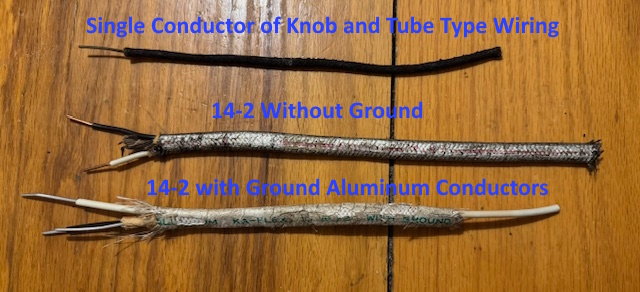

Some Obsolete Wiring Types

Summary

Well I hope this summary of the different types of common electrical cables and conduits we commonly see in residential homes today is helpful. There are many other types of electrical conductors and conduit not covered in this article. They’re coming out with new products all the time.

Great overview of the different wiring types used in residential construction. Really simplified things for me. Thanks.