Both sump pumps and sanitary sewage pumps sit inside a pit and pump out fluids in a similar way but they function in very different ways and serve very different functions. One source of confusion is that the words sewer and sewage can be applied in very different ways. In this article we’re going to try to precede these terms with the proper adjectives.

Two Types of Sewer Systems

Storm sewer– A storm sewer takes storm water, rain water and surface landscape drainage and channels in into a system the municipality has set up to receive it. Sometimes it’s underground catch basins or pipes which eventually channels it to retention ponds or low lying swampy areas. Eventually it makes it way back to lakes, rivers and eventually the ocean.

Sanitary Sewer– Is the system which is set up to take care of waste water from homes and businesses. Typically this waste water is anything but “sanitary” as it contains urine, poop, bath and dishwater from your home so it must be treated properly to make it safe. This water must be handled correctly for heath reasons. So it’s either deposited into the homes septic system or drained into the municipalities waste treatment plant where the water is prepared to go back into the environment.

Two Types of Sump Pump Systems

Well, there may be way more than two types of sump pump systems but we’re only going to discuss the two types that homeowners and home inspectors typically encounter. We won’t be talking about the different types of pumping systems used in various sanitary waste water treatment systems.

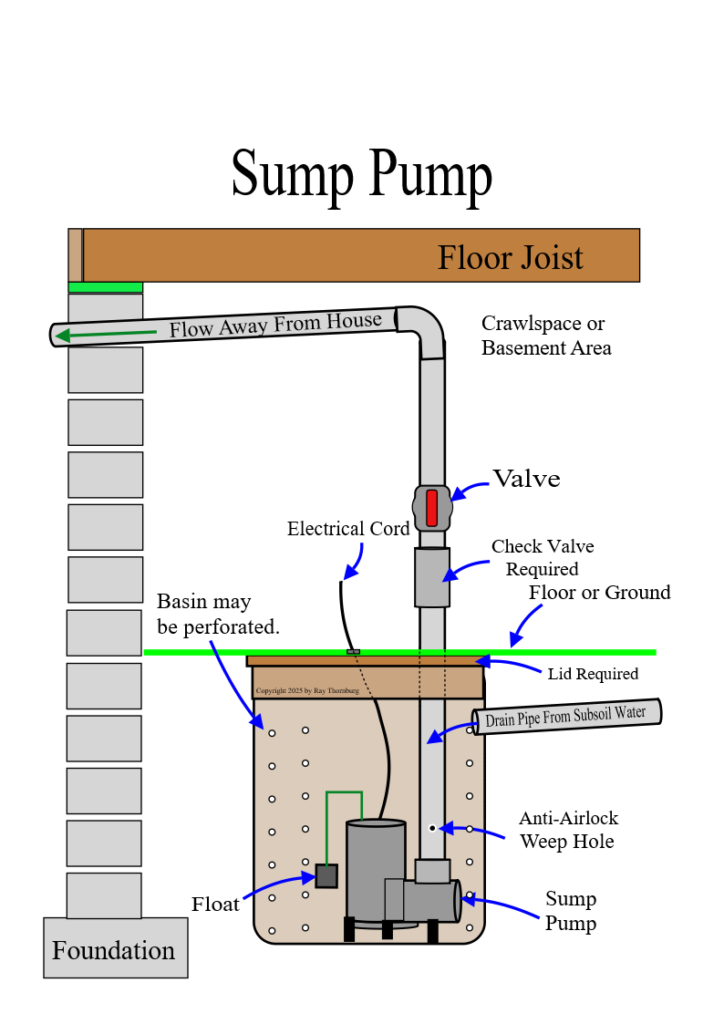

Sump Pump– A regular sump pump is designed to collect subsoil water, rain water or storm water and pump it away from the home in an approved manner. These pumps are often placed in basements or crawlspaces to keep them dry. The most common types are submersible and pedestal types. There are also several type of backup sump pumps which this article won’t address.

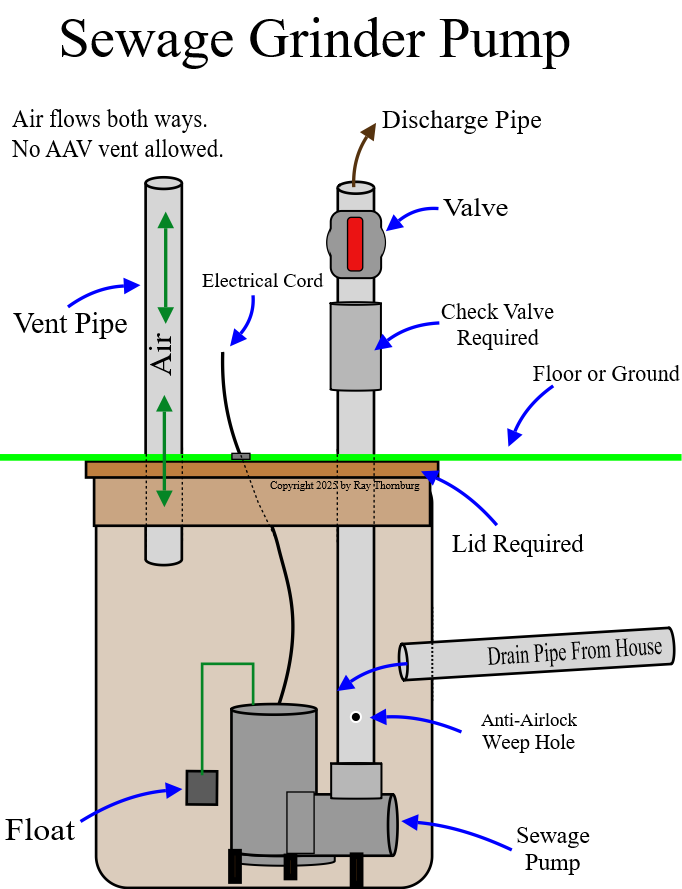

Sewage Pump– A sewage pump and sump pit is designed to handle sanitary sewage from the home. Typically the sewage sump pit receives the sewage by gravity and then when the pit reaches a certain level it pumps it out back into a sanitary sewage treatment system. For instance a basement bathroom might have to pump the sewage from the toilet up to a pipe which flows into the city sewer system. Another common use is when someone builds a detached garage or a pool house with a bathroom and needs to pump the sewage to the house sewage system so it can be then flow to the municipal sanitary sewer system or a private septic tank system. There are four main categories of sewage pumps as follows.

Submersible Sewage Pump– These pumps are designed to be submerged directly into the sump pit and can pump liquids and solids, sometimes up to 2 inches. These are the most common type and 90% of the time this is the type that will be used in a residential sanitary sump pit. The advantages to these pumps are that they’re much less expensive than a grinder pump and much more reliable. These pumps will probably have a 2 inch pipe exiting from the sump pit to carry the sewage to the septic system piping.

Grinder Sewage Pumps– Submersible grinder pumps look similar to the sewage pumps but they have the capacity to chop up (grind) sewage so it can be pumped through a smaller pipe. The advantage of this kind of pump is greater head height and pumping distance. The drawback is since it does grind things up it has a tendency no not last as long. If a sump pit has a grinder pump it’s likely have a smaller exit pipe, like 1.25” instead of 2”. External grinder pumps are often used on RV’s to grind up the sanitary sewage and pump it through a garden hose size pipe to a nearby septic pipe for instance.

Effluent Pumps– These pumps are used to move wastewater that has been partially treated, typically from a septic tank to a drain field. They can handle small solids and are designed for continuous operation.

Other Types- There are other types of pumps used in a variety of ways in Sanitary septic systems. For this article we’re not going to concern ourselves with going off on this tangent.

Two types of Sump Pits

Sump Pump Pit- Typically sump pits that handle subsoil water will be a plastic with holes in it to allow water to seep into the pit. Often they’re surrounded by rock or pebbles and have one or more corrugated drain piping entering the pit so it can receive subsoil water from those drains.

Sump pits are required to have lids to prevent animals and debris from falling into the pit and obstructing the float. The lid will also keep the water from evaporating into the crawlspace (or basement) and thereby raising the humidity in that space. The lids for this type are not often screwed down unless they’re outside. Often the lids are loosely fitted or have a split in the middle to allow access to the pump. If the sump pump is in an encapsulated crawlspace it’s prudent to have one that seals tightly.

A check valve and a full open valve is required in most cases.

A regular sump pit is not required to be vented. However if the sump is located in a living area it might be prudent to seal it tight to keep ground odors or gasses out of the living area.

Usually this type only has one pipe (the discharge pipe) exiting the top of the sump pit.

The discharge cannot be into the sanitary sewer system. Typically any discharge should be about 20 feet away from the structure.

Sewage Sump Pits- Sanitary sewage sump pits accept smelly sewage so have to be sealed tight to prevent sewer gases from escaping.

They must have an air tight lid.

The minimum size of a sump pit is 18” x 24”.

Typically there will be one sewer pipe entering into the pit from the side (under ground) and they’re be two pipes coming out the top. One for the required vent and one for the sewage discharge pipe.

The required vent must be a dry vent and has to follow the plumbing code for drain vents. An AAV (air admittance valve) is not allowed as the system is sealed. So the air has to be able to flow in when the pump activates and out when sewage enters the pit. An AAV vent would only let air in. Improper venting could cause turbulence and siphoning on the building’s P traps. So it has to be vented correctly.

A check valve and a full open valve located on the discharge side of the check valve is required to be installed on the pump discharge piping between the ejector and the gravity drainage system. The valves have to be accessible above the pump cover.

A sewage sump pump will discharge into the building sanitary drain system which will then drain by gravity to a private septic tank or the municipal sanitary sewer system.

Sump Pump Electrical Requirements

Sump pumps must be sized to meet the expected demand. If the sump pump is in the crawlspace then it must be on a GFI protected receptacle at this time. In most cases it should be on its own circuit although it’s not explicitly required. Since the average sump pump draws 10 or 12 amps you wouldn’t want much else on that circuit. The issue we find out in the field on home inspections is sometimes for convenience workmen will tap into another circuit under the home to wire the pump. These other circuits might be for a kitchen or bathroom for instance so wouldn’t be allowed to serve other loads.

The Anti-Airlock Weep Hole

You might have noticed the anti-airlock weep hole in the diagrams above. Most installers will drill this weep hole with a 3/16″ drill but at a slight upward angle to the inside of the pipe as a matter of standard practice. This is to prevent an airlock condition on your system which could prevent it from working. Some manufacturers will provide their own weep hole on the pump itself but it doesn’t hurt to have another one. Caution though. Some small amount of fluid will squirt out that little hole in the pipe. This is why it’s angled upward so as not to spray upward on the lid. Follow the instructions that came with your pump.

Now Let’s see what we find out in the field……..

Common Issues with Sump Pumps

- The most common issue we find during home inspections is amateur installations of sump pumps under the home. Most notably in the way the sump pit is set up. A commercially available professional grade sump pit should be used. Often we find 5 gallon buckets with holes drilled in it used as a sump pit. Most plastic buckets are not made with a plastic which will last. They’ll decay and it’ll be a mess. Often there is no lid. Without a lid small animals and debris can be trapped in the sump pit and interfere with the float. A lid is required.

- Another issue is the lack of a sump alarm to alert occupants in case the pump fails. If a remotely located GFI outlet under the house would flip then the pump could be without power for a long time before it is discovered. By then a lot of moisture damage could occur. So a circuit alarm is a very good idea. There are also some very good battery backup systems on the market now that will power a sewage or sump pump in case the power goes out for a while. The GFI that protects the sump should be in an accessible location. You wouldn’t want to swim through 6 inches of water in a flooded crawlspace to press the reset button would you?

- Extension cords should not be used. Extension cords are only rated for temporary use. If you want power to a sump pump it needs to plug directly into a properly wired outlet.

- For sanitary sewage pumps clogging and motor failures can be issues. Grinder pumps are particularly known for failures. Be sure to never flush wet wipes, tampons or anything besides toilet paper down the toilet. Also rinsing too much grease down the drain can affect the float mechanism. The grease cools off after it enters the sanitary septic pit and floats on top interfering with the float.

- For all sump pumps issues with the float switch operating correctly are common problems.

- Maintenance evaluations should be performed occasionally to make sure there is no sludge build up in the bottom of the pits and the float switch works correctly. Watch for unusual sounds or continuous or intermittent operation.

- On sump pumps in cold climates freezing of the sump drain line is a common issue.