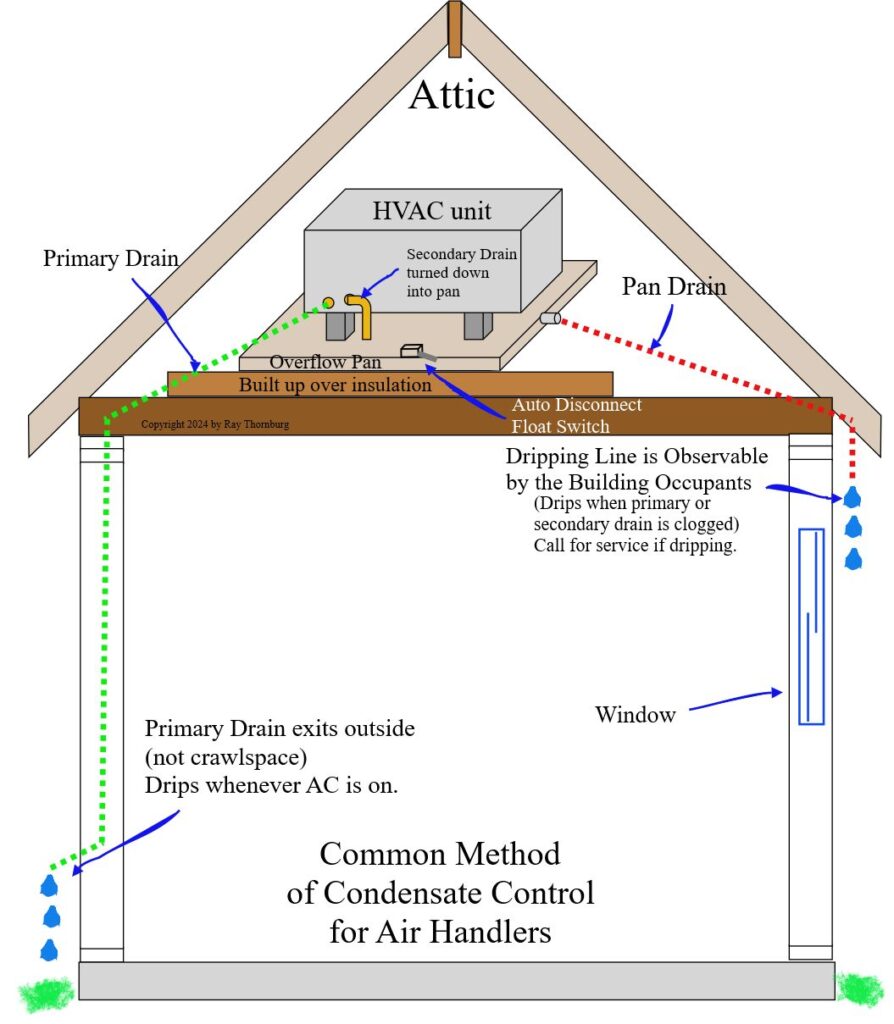

Modern air conditioners can remove between 8-20 gallons of moisture from the air every day. So on modern air conditioners provisions have to be made to reliably remove any collected water that the air conditioner removes from your home air to a an appropriate place (usually outside). To do this the air handler needs a pan under the evaporator coil and a drain. If the unit is in the attic or another place where a leak would cause damage then a pan is required. The picture below shows a common method of condensate control on a modern home.

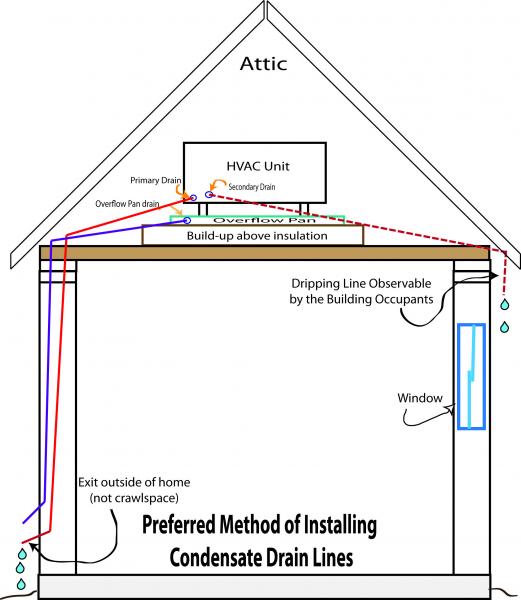

The next picture below shows the preferred method of condensate control. In this method all three drain lines are piped outside, the primary, secondary and the overflow pan drain. Water should only be draining out of the primary line when the AC is on. If water drains out the other lines then you have a problem and likely the primary drain line is clogged.

Since the method below requires additional work and some extra piping material I rarely see it done this way. It does make more sense as the secondary drain will be the first place to leak when the primary drain clogs. This would avoid rusting out the pan in many cases.

The Trap

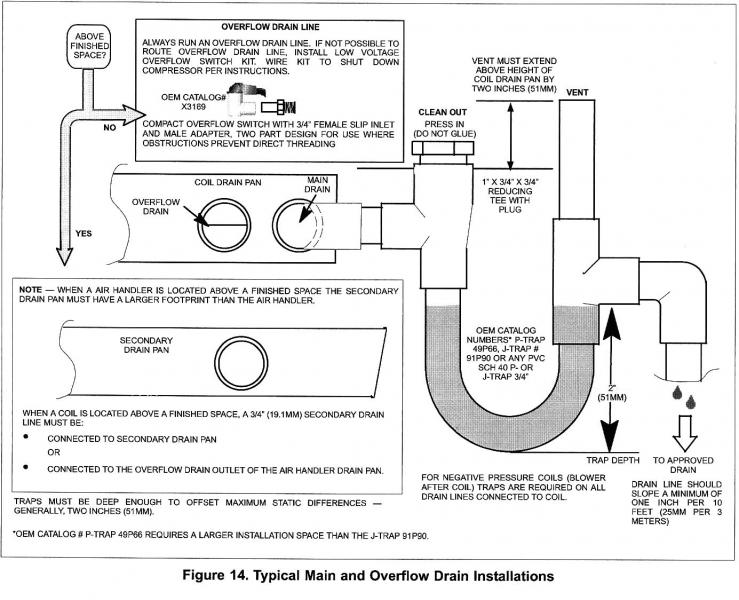

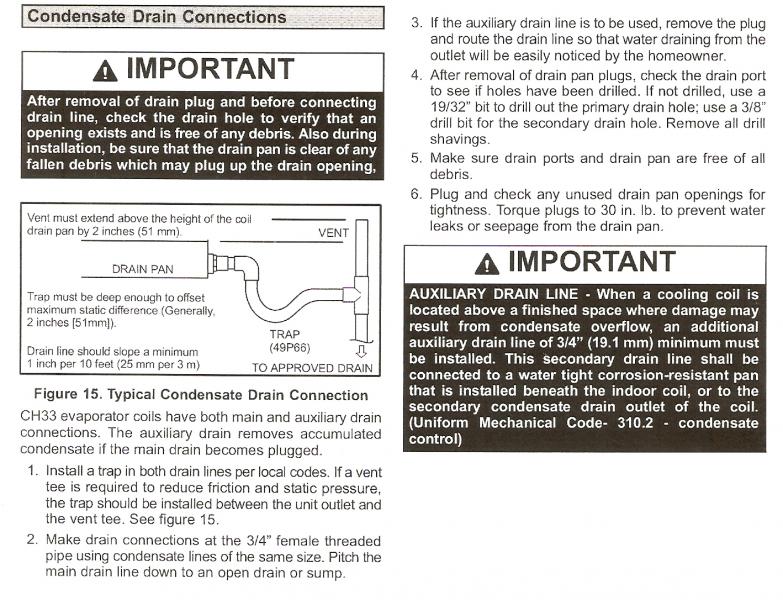

So why would a condensate line back up? Two reasons actually, insufficient slope for the primary drain line and failure to clean the trap. The trap is the U shaped section of the primary drain which acts much like a P trap under the kitchen sink. On a P trap under the sink it prevents sewer gases from entering the house. On an AC evaporator it prevents air from blowing out the drain line. It also ensures that the condensate water will properly drain; because the air pressure of the blower fan can disturb how water will drain without a trap, (and for other reasons). Since most manufacturers now require traps for their systems you can expect to see them on almost all modern AC systems. The picture below shows how Lennox wants their trap to be configured on this particular unit. (picture used under fair use)

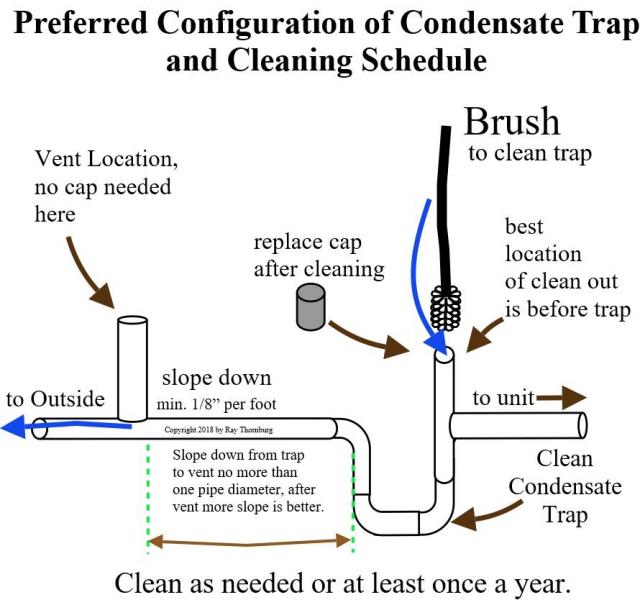

Clean The Trap

The trap should be cleaned occasionally (at least once a year) because they have a tendency to get clogged up. See the water in the trap in the picture above? It’ll get gummed up. If a clean out is installed at the trap then this cleaning job is much easier. We recommend using a small aquarium brush to remove gunk in the trap and pouring some disinfectant (like vinegar) into the trap. This is very important! Develop a maintenance plan to scrub the trap clean! Don’t be lazy….get up there and scrub it out!

Drain lines should be well supported through out because a sag is actually another trap and double trapping will cause a back up. The primary and secondary drain lines must be piped separately. The picture below show how to clean the trap.

The Missing Cleanout

In the example above checking the trap is easy. Just take the cap off and look to see if its about to clog up. More often then I’d like to see, the technician does not put a clean out at the trap or leaves it out completely. Without a properly placed clean out the trap will be hard to clean and hard to check to see if the trap is clean. While we think this is a mistake it’s not always his fault. In the install instructions below the picture shows the trap without a clean out. (picture, fair use )

The Trap Vent

The vent after the trap serves to keep the trap from siphoning dry due to differences in the air pressure. Yes this can happen (at least theoretically). You may think that the slow dripping of the HVAC drain is unlikely to develop siphoning force great enough to empty the trap but there’s also the air pressure inside the cabinet from the fan motor to consider. If the system has a trap it’s best to have a uncapped vent on the downhill side after the trap.

The Overflow Pan and Drain

A secondary auxiliary (overflow) pan is now required if a leakage could cause damage. This pan should be at least 3” bigger than the unit on all sides. The drain line for this does not need to be insulated or trapped but should exit in a place outside where the occupants of the home can see it dripping should the primary drain back up. There should not normally be water in this pan as it is there in case the primary pan clogs up. If there is water in this pan call a service person.

There may be overflow float type switches installed on the secondary pan or in the drain line or both to cut power to the unit in case of overflow. If this device is on the secondary (overflow) pan then a drain is not required for it. Some types of designs (i.e. down flow units) may not have a secondary pan and in that case a high water cut off is installed in the primary pan.

Rules About AC Condensate Disposal

· Condensate may not drain to public way.

· Drainpipe min ¾” with 1/8” slope per foot.

· It may drain to an indirect was receptor ( i.e. laundry tub, laundry standpipe, lavatory tailpiece, tub overflow pipe)

· It may not be directly connected to waste or vent pipe.

· If condensate blockage would damage building components then install one of the following.

* Secondary drain to a conspicuous point of disposal.

* Auxiliary pan with a drain to a conspicuous point of disposal. Auxiliary pan must be separately piped. M1411.3.1 #1

* Auxiliary pan with a detector and drain fitting.

* Water level detection device in primary, secondary, or pan with interlocked cutout.( shuts equipment off in case of an overflow.

· Down flow units with no secondary drain and no way to install auxiliary drain pan requires an internal blockage detector with interlock cutout.

· No drilling saddle type fitting for discharge into drain, waste, or vent stacks to accept condensate disposal.

· Auxiliary drain pans should be 1.5” deep minimum and 3” larger than the unit or coil dimensions in all directions.

· Supports inside of pan to support equipment shall be water resistant and approved. (Wood or treated wood is not allowed because wood can decompose and treated wood has salts in it which can cause corrosion.) Recommend use commercially available supports.

References IRC M1411-M1411.6

High Efficiency Gas Furnace/AC Units.

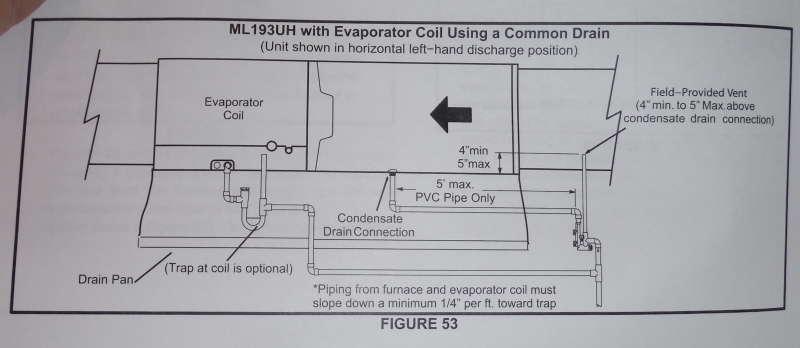

A high efficiency gas furnace (HE) will have two condensate lines. You can tell if you have a HE furnace because the exhaust flue will be made out of PVC. This is possible because almost all heat is extracted from the flue gasses before they exit up the pipe. The downside is that this type of system produces an acidic condensate which must be collected and piped out. So you’ll have a condensate line for the evaporator and the exhaust condensate. Both require their own trap. The exhaust gas condensate line is very important to get right for safety. Be sure to follow the manufacturers instructions to the letter. Below is an example of a HE unit showing the evaporator condensate line and the exhaust condensate lines. In this case it shows the lines tied together in a particular way downhill of both traps.

The Automatic Float Disconnect

You may have noticed that the systems may have float switches installed in different locations. These detect when the water gets too high in the pan for instance and disconnects the power or the thermostat. They can be located in the pan or the secondary, primary drain lines at the installer discretion. There are two types-

- Latching Switch- will shut the system down and will stay in that position until it is manually reset or another action is taken to reset it. This kind of switch will force you to call for maintenance as the system will stay off until reset. These can be used in places where they want to prevent further complications from an overflow condition.

- Non-Latching Switch- These switches will shut the system down when the water level makes the float move up and turn it back on when the water level falls to an acceptable level. This kind of switch will cause intermittent operation for instance if a drain is only partially clogged.

Float switches are subject to failure if they get gelled up with algae which can happen especially if located in a condensate pump.

Insulate the Primary Condensate Line

The primary condensate line should be insulated in the attic to prevent condensation from forming on the condensate line, dripping onto ceiling surfaces and causing damage which can and does happen. I’ve seen it many times. I site the following references.

M1412.3 Insulation of piping.

Refrigerant piping, brine piping and fittings within a building shall be insulated to prevent condensation from forming on piping.

N1103.3 Mechanical system piping insulation. Mechanical system piping capable of carrying fluids above 105°F (40°C) or below 55°F (13°C) shall be insulated to a minimum of R-3.

503.2.8 Piping insulation from the energy code

All piping serving as part of a heating or cooling system shall be thermally insulated in accordance with Table 503.2.8.

Now let’s take a look at what we find out in the field.

There really is no end to the nightmarish inspection photos I could show. One thing is certain. One of the top defects home inspectors find are issues with how the condensate lines are configured or maintained. Keeping the trap clean can be an easy homeowner maintenance chore provided the unit is placed where it can be accessed easily and safely. HVAC units are often placed in attics with poorly constructed walkways or clearance. The elderly or infirm can hire a technician to keep the traps clean in this situation.