Combustion air is the air a fuel burning appliance needs to keep a fire burning. An appliance burns fuel but it also burns air. So for natural draft gas appliances the experts have calculated how much air it burns and how much air it will exhaust up the flue and wrote some requirements for safety. Without proper combustion air the flame will go out or not burn correctly which is a hazard. It’s not just a performance issue. Lack of combustion air can also cause issues with carbon monoxide (a deadly, invisible, tasteless, odorless gas) buildup in the home. Think of it like this. If an appliance is starved for air it won’t “draw” right up the flue pipe and that could mean back spillage of exhaust into the room. So naturally you don’t want this.

There are a lot of rules concerning combustion air (CA) and the methods used. Basically these rules help ensure safe and efficient operation of the appliance. This discussion will focus on some of the basics. Please follow the manufacturers recommendations and any applicable codes. I used IRC 2009 2407. 1-12 for my reference.

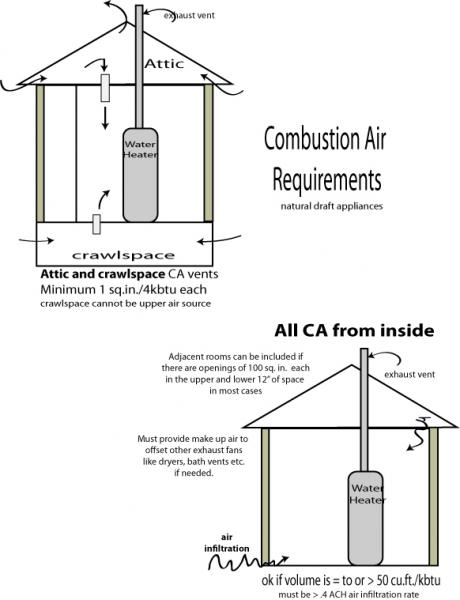

If a gas appliance is placed in a confined space like a closet or utility room some provision must be made to supply the unit with combustion air. However if the room is large enough like a ventilated attic or double car garage it may not need additional provisions for CA. The first step is to find out the BTU rating of all appliances in that space. This information is usually located on a data plate attached to the appliance. The next step is to determine the volume of the room the appliance is in (in in cubic feet). (that’s LxWxH in feet) If the room is over 50 cu.ft. per 1000 btu and has a known air infiltration rate of .4 ACH (air changes per hour) then you may be good to go. Otherwise use one of the methods shown below to supply your appliance with the proper amount of combustion air.

But first let us practice a little math.

Typical gas water heater is about 40000 btu. (40K)

We have to have 50 cu. ft. per 1000 btu. so….

50 x 40 = 2000 cf

…….So we need to place this water heater in a 2000 cu ft. room (about the same size room as a one car garage) if it has a known air infiltration rate of .4 ACH (air changer per hour). If you don’t know then it’s assumed that it doesn’t. .

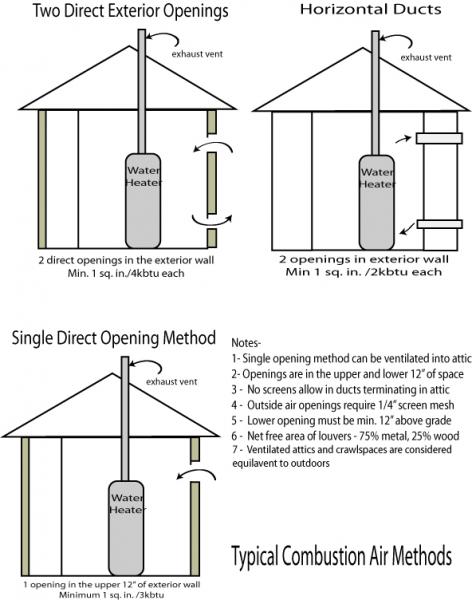

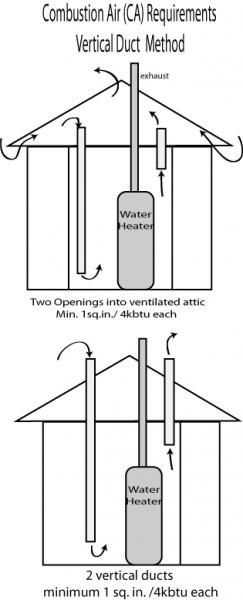

Note that any room smaller than 50 cu. ft per 1000 btu is defined as a confined space and vent holes for combustion air will have to be provided. We will need one sq. inch of upper and lower ventilation for every 4K BTU that the appliance is rated for. So for our 40K btu water heater example we will need two 10 sq inch openings- one high and one low. (40K divided by 4K for each sq inch of ventilation ). A 4 inch dryer vent is 12.6 sq inches so we can use the vertical duct method to draw air from a ventilated attic. Remember both vents need to be the required size (in this case 10 sq inches).

Now let’s look at some different ways to satisfy combustion air requirements.

Adjacent Rooms

Rooms that communicate directly with the space in which the appliance is located through openings not furnished with doors can be considered as part of the required space.

Buildings with Unusually Tight Construction

Buildings or (spaces) with unusually tight construction must take all the combustion air from outside the thermal envelope. reference M1701.1.1

Commentary- There is no clear definition of “unusually tight construction” but most modern homes built after 1986 would meet that definition. Homes that have house wrap, double pane windows, storm window which are well sealed, and sealant applied at wall, plumbing and other penetrations would meet that definition. Also some older homes which have been remodeled may meet that definition. An air handler located in an encapsulated attic would also meet that definition so it would need combustion air ducts.

Exhaust Hoods

Exhaust hoods capable of exhausting 400 cubic feet per minute shall be provided with an equal amount of make up air. reference 2021 IRC M 1503.6

Commentary: So what this means is if you have a nice powerful exterior vented kitchen exhaust fan which can exhaust 400 cubic feet per minute of air then your home will need a make up air vent system. This type of system is typically installed with your HVAC system to draw in outside air. Barometric pressure switches sense when the exhaust fans operate to open the dampers to allow fresh air in.

Dryers

Electric dryers don’t need combustion air but all dryers need make up air. Make up air is needed to “make up” for air which is exhausted by appliances. If a dryer is in a small closet the requirement is for 100 sq inches of ventilation if the dryer can exhaust more than 200 cfm. A dryer in a small room with the door closed can suffer from reduced efficiency and the exhaust vent will be more likely to clog if make up air is not supplied. The provision for this rule is found in IRC 2012 G2439.4 (614.5).

Note* Do not place a dryer right next to a gas water heater as it can pull flue gasses back into the house. Which can cause death or sickness. Also lent will eventually clog the ventilation holes the water heater uses for proper operation and may cause the pilot light to fail. If this has to be done you’ll want to provide combustion air and make up air as required.

Direct Vent Appliances

Not all gas appliances are natural draft. Some appliances are direct vent type and do not need combustion air because they have a built in method of drawing combustion air in through a pipe that also exhausts the flue gases. In most cases it is a type of double pipe, though sometime two separate pipes are used. On high efficiency furnaces for example exhaust and combustion air is drawn through a PVC type pipe. The manufacturer’s instructions will show how to vent these appliances and supply combustion air. Many of these instructions can be obtained online. Some of these (like tankless water heaters) have conversion kits to allow for either direct vent or traditional venting methods. Always check the instructions out to see which method is best suited for your situation.