CSST stands for corrugated stainless steel tubing. This type of gas line tubing is very popular among builders and contractors because of its ease of use, flexibility and its ability to save on labor installation costs especially over black iron pipe. Although there have been a few concerns with this type of pipe over damage from nearby lightning strikes. This may have caused the rather thin pipe to burst; which resulted in fires. It is thought that the proper installation and bonding of this piping system makes it a safe alternative to black pipe. Millions of homes have csst installed in them.

CSST typically has a yellow pvc or polyethylene outer jacket which mainly serves to protect the stainless steel tube from chemicals and abrasion.

The flash shield type is another type with a typically black jacket that has an additional layer of protective coating which is supposed to dissipate electrical energy for improved lightning protection.

The manufacturer of these products specify how they are to be installed and all installers must be certified by the manufacturer. All parts used with a system must be sourced from the same manufacturers system. In other words don’t mix brand A with brand B. Below are some abbreviated and paraphrased rules for csst gas line installation. For the complete rules please download a copy of the instruction manual for the brand of csst that is being used. Get the tracpipe install guide here. Here is the gastite install manual.

Common Requirements for CSST

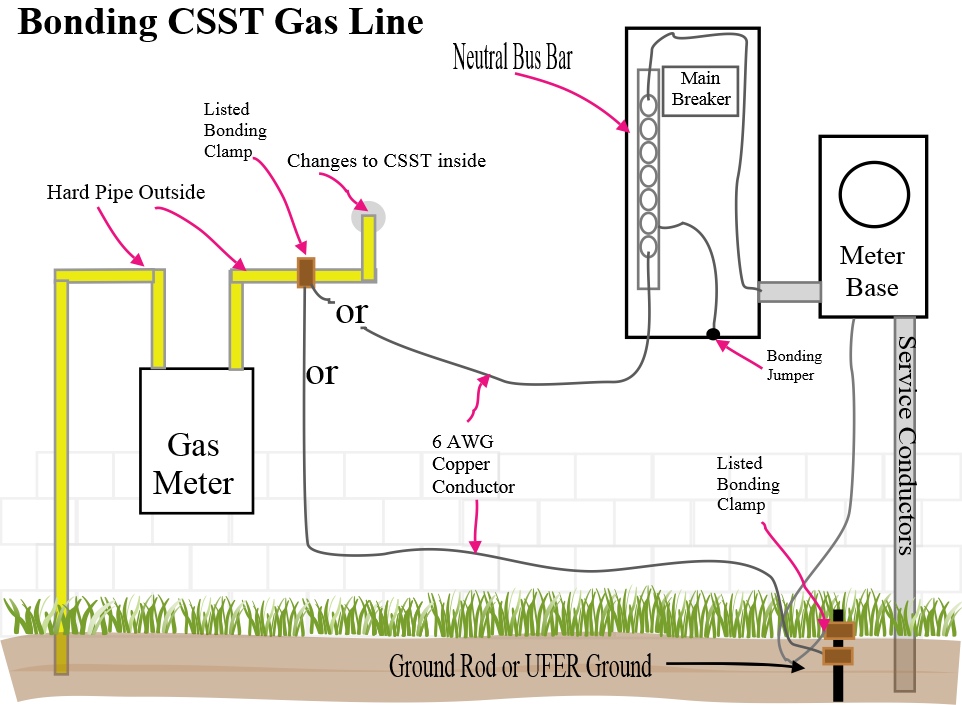

· System should be properly bonded and grounded. For systems with one or more segments of CSST. The bonding conductor shall be no smaller than #6 AWG copper or equivalent. The bonding jumper shall connect to a metallic pipe or fitting between the point of delivery and the first downstream CSST fitting. The maximum length of this bonding jumper is 75 feet. References irc 2006 G 2411.1, irc 2012 2411.1.1. For more info about grounding and bonding go here.

Gas piping other than CSST type shall be considered to be bonded where it is connected to appliances that are connected to the equipment grounding conductor of the circuit supplying that appliance.

· Care should be taken to maintain as much separation as possible from other electrically conductive systems in a building. This includes chimney liners, metal duct systems and electrical cables.

· Do not install in a chase that includes a metallic chimney liner or appliance vent that protrudes through the roof. If it is necessary to do this then the metallic chimney needs to be grounded and bonded and separation from the csst must be maintained.

· Rigid termination of tube ends required.

· Csst is suitable for outdoor use. The outer jack is uv resistant and flame resistant.

· Tubing must be protected from contact with sharp objects including metal cabinet edges or metal studs edges.

· Do not bend the pipe too much. Bend radius specifications are in the manual.

· Support typically- non rooftop non wall cavity- vertical or horizontally- 3/8” pipe support every 4’. Support ½” pipe every 6’. Support ¾” or larger pipe every 8’. Pipe shall be supportive but not restrictive.

· Holes drilled for pipe should be ½” larger than the pipe.

· Most CSST fittings are approved for concealed spaces.

· Manifold stations, shut off valves and regulators cannot be concealed.

· Strike plates are required.

· When installed outdoors seal gaps in covering with a self bonding silicone tape.

· When installed alongside the outside of a structure it needs to be protected inside conduit or a chase up to 6’ in height. Elsewhere it needs to be protected where subject to damage.

· Cannot be run within ductwork.

· Must be protected by a watertight conduit ½” larger than the pipe when ran through masonry.

· Moveable appliance must use a stub out with an appliance connector.

· Non moveable appliance can be directly connected.

· Drip legs and shut off valves must be securely mounted.

· When an appliance has a vent that protrudes through the roof then contact between the csst and the appliance cabinet is prohibited. Certain CSST products excepted ( i.e. the black jacketed flash guard type products.)

· When roof mounted it must be 3” or more off the roof and supported with appropriate clamps and no less than 6’ apart. 1” diameter pipe or greater- 8’ apart.

· Pad mounted equipment (i.e. not connected to building) must use an appliance connector.

· Can be used in a gas fireplace. Not a wood fireplace. ( must verify with the manufacturer’s instructions first) Brands vary.

· Cannot be buried directly. If it is buried then it must be in watertight conduit ½” bigger than the pipe sealed to prevent water entry. Typically no venting is required by the manufacturer in this instance. Check local codes.

· Regulators in vented area or with vent limiters.

· Sized and support per manufacturer’s tables.

· Repair if crush depth is more than 1/3rd the diameter of piping.

· System should be tested to 1.5 times the working pressure but not less than 3psi. reference Irc 2006 G 2417.4.1

Let’s talk about grounding and bonding again. Study the pictures below.

Commentary on the above picture.

A guy from Texas sent me this photo. It shows the damage to a CSST gas line from a nearby lightning strike. This is the reason why CSST should be separated as much as possible from electrical cables and properly bonded. The man said it was a miracle his house didn’t burn down.

Installers have to be trained in the CSST piping system they use. We suggest finding the current install manual for the system in use and read it thoroughly. Every system requires the installer to only use their own products for the installation process.