P- Traps

Home inspectors have to inspect the visible portions of the plumbing system to make sure there are no leaks, concerns or configuration issues. In the house, the traps for the sinks are visible below the sink in the cabinet under it. Under the home, typically the only traps which are visible would be the tubs and showers. In the attic, the venting portion of the drainage system is typically the only visible part. Below is an overview of some of the components and how they should be configured.

A P trap is that u shaped pipe under the kitchen sink. Its purpose is to hold a little water in the trap in order to keep sewer gases from entering the building. Sewer gasses can be dangerous so we don’t want them in the home. In order to keep the sewer gasses out and sewage flowing smoothly code officials developed rules that must be followed for proper drainage and safety. In addition to traps; vents are needed to keep pipes from gurgling and to help liquids to flow through the pipe. Waste water will not flow through a pipe that’s not vented. Imagine drinking soda through a straw and putting your finger over the end of the straw while you lift it out. So the soda stays in the straw until you lift your finger. It’s the same way with house plumbing. It has to be vented.

So below is list of the most common things to look for when taking a peek under the kitchen sink. First we’ll talk about Traps. References IRC 3201.2-6

· Each fixture requires a trap except toilets which have a integral trap and fixtures which are close together can use the same trap.

· Fixtures sharing a trap max 30 inches apart horizontally.

· Trap seal minimum 2” to maximum of 4”. (This is how much water is held in the trap see pic)

· Set traps level and protect from freezing.

· No S traps, bell traps, drum traps, or traps with moving parts or interior partitions.

· Sized per 2006 irc table 3201.7

· Trap size equal or greater than fixture outlet size.

· No double traps. No corrugated or flexible traps.

Notice in the picture below the tailpiece, trap arm and the allowable trap depth. A trap that’s too deep will clog often.

Tailpiece

The fixture tailpiece is the pipe that comes straight down from the drain. Here are some rules for them. References IRC 3201.6,2706.2

· Fixture tailpiece maximum 24” vertical distance with the exception of a washing machine standpipe which is 18-30” per IRC 2706.2.

· Maximum 30” horizontal distance between vertical tailpiece and p trap vertical tailpiece.

· Directional fitting required for the discharge of the disposer or dishwasher.

Study the picture below that has all the important components labeled. Notice the air admittance valve (AAV) which allows venting in this situation. The Trap Arm is after the P trap and cannot slope more than 1 pipe diameter to the vertical drain and vent stack.

Trap Arm

The trap arm is the horizontal pipe that extends from the p trap to the vent stack or waste stack. References IRC 3201.6-7, 3105.1-3,3201.1

· Trap must be same size as trap arm.

· Trap arm length must be a minimum 2x trap arm diameter.

· Trap arm length per 2006 irc table 3105.1

· Maximum Slope of pipes less than 3” diameter is ¼” per foot.

· Total fall of trap arm is one pipe diameter. ( i.e. if the minimum pipe size is 1 ¼” then the max trap arm length is 5’. 5/4 divided by ¼ = 5’)

· Only 1 trap permitted per trap arm except 2 traps allowed to join through a double-wye fitting to a common vent.

· Tubing trap require trap adapter

· Max 1 slip joint allowed on outlet side of trap.

· Clean out required for change in direction of more than 90 degrree in a 3” or less diameter pipe.

· Slip joints required to be accessible.

Vents prevent pressure differences in the pipe so that water doesn’t get sucked out of the trap.

Vents

You can see plumbing vents sticking up through the top of the roof of most homes. There are a lot of rules about venting so I’m only going to touch on the most general ones here. References IRC 3101.2.2.1, 3101.3, 3104.3, 3104.2, 3105.2-3

· All fixture traps require venting

· Vent system is not to be used for any other purpose.

· Slope vents down to drain to soil or waste piping.

· No vent opening below trap weir except toilets.

· No crown vents – must be min. 2 pipe diameters from trap.

· Horizontal dry vents min 6” above flood level rim of fixture. Not ok under FLR. Commentary- If the horizontal dry vent was below the FLR of the fixture then if a clog happened in the drain line the sewer water could back up into the horizontal dry vent and you would not know you had a clog. So you have to bring it up higher before turning it horizontal to the vertical vent.

· Minimum 1 vent to outside.

Air Admittance Valves

There is a type of vent called an air admittance valve. AAV is used where it is impractical to put in a regular vent, like an island sink fixture. Some of the same rules apply to AAV but here are a few particular to AAVs. References IRC 3114.2-8

· OK at individual, branch, circuit and stack vents.

· Individual and branch type AAV to vent only fixtures on the same floor level and that connect to a horizontal branch drain.

· Individual AAV min 4” above fixture drain.

· Stack type AAV min ^” above FLR of highest fixture.

· AAVs terminating in attic min 6” above insulation.

· Space containing AAV must be accessible and ventilated.

· AAVs not ok for sumps or tanks.

The picture below is an example of how not to vent a fixture. Water rushing down the tailpiece into the drain will create a pressure difference which may siphon the trap dry allowing sewer gases into the home. The fall of the trap arm cannot exceed one pipe diameter.

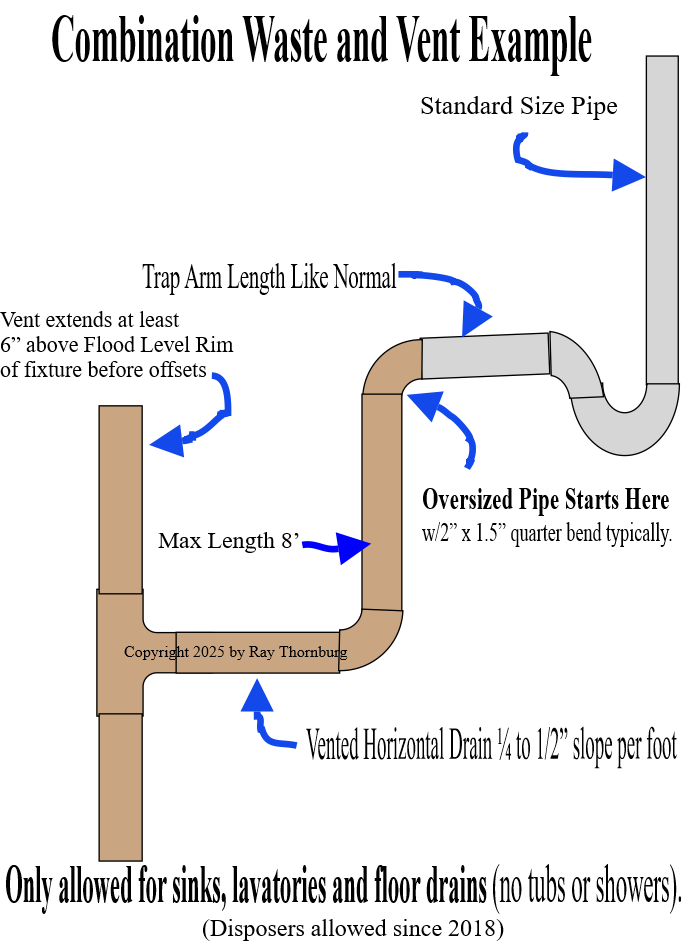

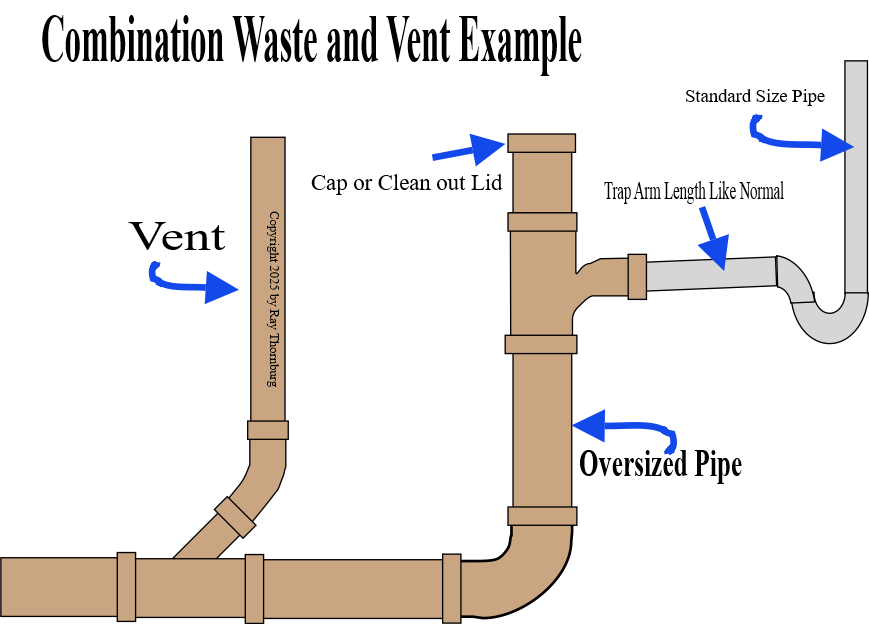

Combination Waste and Vent Drain

The one exception to having the trap arm directly connected to a vent/drain is when the drain diameter is much larger than the trap piping size. For instance a sink draining into a 3 or 4 inch drain line which extends up vertically past the trap arm by at least 4 inches. The idea is that water will never completely fill the drain pipe so the trap will not siphon dry. P3111.1 The rule is that a combination waste and vent shall not serve fixtures other than floor drains, sinks and lavatories. After 2018 a garbage disposer is also allowed on this type of setup. So if you see this configuration on a tub, shower or dishwasher, it is wrong.

Since the siphoning effect begins in the trap arm it is ok to oversize the trap arm as far as I know. The picture below shows a combination wasted and vent drain.

Bends, Elbows, Tees and Wyes

I thought I’d spend a moment talking about fittings in drain lines. Basically there are two parts of a plumbing system, vents and drains. Essentially drain line fittings need to be directional whereas vent couplings can have a sharper turn. (Caution: The names of the fittings can be confusing). A 1/4 bend (1/4 of a circle or 90 degrees) is used in the drain line whereas the 90 degree elbow in the picture below (in yellow) is used for the vent portion of the plumbing. Using a sharp elbow in the drain line will cause a clog point so you should restrict their use to the venting system. So to recap, the sharp 90 degree elbow is only allowed to be used in the venting portion of the system.

When evaluating a plumbing drain system it is helpful to understand what portion of the drain system (vent or drain) you are looking at and what was the plumber trying to accomplish (drain a sink or vent a toilet) for example. On new construction like a pre- drywall inspection it is easy to trace the piping visually. On older home with several remodels much of the piping is behind wall coverings or under insulation so the task is more of a challenge. The inspector will want to visit each plumbing location like kitchens and bathrooms before inspecting the crawlspace for example.

The sanitary tee in the picture below at left (in blue) is only used where a drain goes from horizontal to vertical. It cannot be used in any other position on the drainage portion of the drain system. However it can be used in different ways on the vent only portion. On the vent portion the sanitary T is turned to facilitate a downward direction from the roof to the sewer. A regular tee (not pictured is way too sharp to use for anything but a vent.

The wye (in green) is used in a variety of circumstances (except fixture connections). A wye or long turn wye (not pictured) should not be used in trap arms.

There are many different types of fittings but the bottom line is directional fittings are required to be used in the drainage portion of the plumbing system. So if you see a 90 degree (vent) elbow used in part of a drain (after the trap) it is wrong.

See the picture below for examples.

Toilet Venting

One subject I haven’t touched on is toilet venting….yes toilets need venting too. On a toilet the trap is built into it. If you look carefully at the side of the toilet you can see it. So the vent would come off the toilet drain directly below the toilet flange in much the same way as a sink vent comes off the trap arm. Vents for a toilet are harder to confirm because they are mostly out of sight (behind walls, under the slab, etc.). If you hear gurgling in a nearby drain or small bubbles rising up through the toilet bowl then suspect a vent issue. Frequent clogging can suggest a vent issue, an improperly sloped pipe under the home (or other issues).

Inspection Photos

Now let’s see what we find out in the field.

S traps like the one shown above will siphon dry and will allow sewer gasses into the home, so are not allowed. A plumber will have to fix this one.

In the above picture the trap is too deep and the trap arm dips down too much. A trap which is too deep will clog easily. The distance the trap arm can slope downward is limited to the diameter of the pipe. In this case it looks like 1.5 inches. So a trap like this could siphon dry easily, thus allowing sewer gasses into the home.

A double trap like the one shown above is not allowed. One or the other will clog up easily.

Codes only allow for piping which has a smooth interior surface (self scouring). These type of flexible piping is often used by inexperienced people as a quick way to solve a problem. Sometimes they’re used as the tail piece and sometimes the trap. The “folds” on this one is not as big as some I’ve seen. Nevertheless they are not allowed.

Can you spot the defect in the drain above? There really is no trap to stop the sewer gasses from coming into the house. The trap coming of the dishwasher is useless. A real plumber will make short work of fixing a scenario like this; but the average person just doesn’t have the knowledge nor does he carry the connections and pieces required to fix a job like this.

The leak in the picture above is obvious. What’s not so obvious is that this trap also serves a bathroom sink which has a trap already in the cabinet under it. So besides the leak this is also double trapped which is not allowed. The only traps an inspector should see in the crawlspace poking through the floor is the ones for the tub or showers. The AAV vent should be in the cabinet under the sink.

Vents are required to slope towards the ground (building sewer). In the picture above there are no support straps so the vent is sloped the wrong way. This has resulted in it filling up with water thus blocking the vent. Horizontal PVC piping is required to be supported every four feet.